Dosimeter

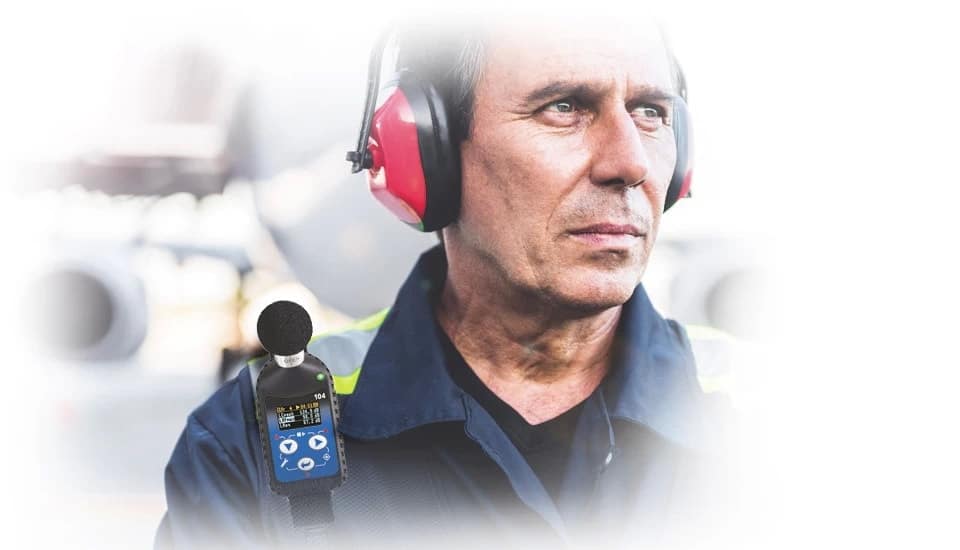

A dosimeter is a portable measuring instrument that is worn on personal clothing. Usually, a dosimeter is attached to clothes with mounting clips, hence the popular name badge dosimeter.

A dosimeter is a portable measuring instrument that is worn on personal clothing. Usually, a dosimeter is attached to clothes with mounting clips, hence the popular name badge dosimeter.

A dosimeter is a portable device designed to measure cumulative exposure to physical agents like noise, vibration, or gases during a work shift. Especially vital for workers who frequently change locations throughout their day, dosimeters are typically attached to clothing using mounting clips, earning them the common nickname “badge dosimeter.”

A personal dosimeter is a compact device worn on an individual’s clothing to measure their exposure to radiation, noise, or chemical gases. The term “personal” signifies that the dosimeter is specific to one individual, tracking their distinct exposure levels. This contrasts with area monitors, which gauge exposure levels in a designated location. Personal dosimeters, often small and lightweight, can be worn as badges or secured to clothing with mounting clips. They are pivotal in monitoring workplace exposure, aiding in the protection of workers from potentially harmful agents.

Dosimeters are used in industries like nuclear power, healthcare, manufacturing, and construction where workers are exposed to dangerous physical agents. Dosimeters are very important for keeping workers safe and making sure that safety rules are followed because they allow accurate and continuous monitoring of exposure levels. They are also an important way to find out about possible health risks and figure out what steps to take to reduce exposure. Dosimeters are also used in research settings to measure physical agent levels in experimental environments (for example, airspace with zero gravity).

An intrinsically safe dosimeter is a measurement device designed to meet stringent safety regulations, such as those outlined by ATEX or IECEX. Designed for environments at risk of explosions, these dosimeters are indispensable in workplaces like mines, refineries, and petrochemical plants, where the presence of flammable gases, vapors, or liquids is common.

To uphold their intrinsic safety, these dosimeters incorporate specific components and materials that prevent sparking or excessive heat generation, even under severe conditions or significant mechanical stress. Such features are paramount to avert potential explosions or fires in perilous settings.

Employed in various industries and hazardous workplaces, intrinsically safe dosimeters not only provide precise measurements of exposure to radiation or other physical agents but also play a pivotal role in safeguarding both workers and equipment.

Dosimeters operate by tracking exposure to harmful physical agents over a specific duration. These devices capture, analyze, and store this data, facilitating subsequent processing and reporting. Depending on the physical agent they’re designed to measure, dosimeters are equipped with different sensors. For instance, they might incorporate microphones for noise, vibration sensors for mechanical disturbances, or specific filters for certain chemical agents.

A personal dosimeter’s wear time should align with the measurement standard set for the specific physical agent under observation. Generally, these devices are worn for a complete workday, often defined as a minimum of 8 hours. However, depending on workplace conditions and the physical agent in question, certain standards might stipulate shorter or longer monitoring durations. For instance, in scenarios where workers remain in a singular location with uniform exposure conditions, a reduced monitoring period of 5 hours might suffice. It’s crucial to adhere to the manufacturer’s guidelines when setting up and wearing the dosimeter. Removing it mid-monitoring can compromise data accuracy. Notably, many dosimeters come with programming options to omit data during breaks, ensuring the integrity of exposure measurements.

Before and after each set of daily measurements, dosimeters should be calibrated to make sure they are accurate and to confirm the results. In addition, dosimeters should be verified for accuracy at least once every two years and every time any physical damage is reported, such as dropping the dosimeter on the floor. It is also important to follow the manufacturer’s recommended calibration schedule for the specific dosimeter model being used.

There are cost-effective options for purchasing dosimeters. It is important to consider factors beyond the initial purchase price, such as the cost of required accessories, calibration, and maintenance over time. Some manufacturers offer bundled packages that include dosimeters and necessary accessories, which can provide cost savings. Additionally, purchasing from a reputable seller that offers calibration and technical support services can also help save money in the long run. It is also important to consider the level of accuracy and sensitivity required for the specific application, as choosing a lower-accuracy or lower-sensitivity dosimeter may result in cost savings but may not provide adequate protection for workers.

The choice of the right dosimeter for the job hinges on the specific workplace conditions, the physical agent targeted for measurement, and the mandated accuracy class in regulations.

Types of Dosimeters:

The particular agent and the workplace’s measurement regulations, such as standards set by ISO or OSHA, typically dictate the type of dosimeter chosen.

Classifications by Sensitivity:

Safety Classifications:

When choosing a dosimeter, it’s crucial to consider the specific needs of the workplace and application. Here are some key features and benefits of various dosimeter types:

Classification:

Battery Life: The duration a dosimeter operates on its battery can vary, with some models boasting extended lifespans of weeks or even months.

User-friendliness: Certain dosimeters come equipped with mobile apps or software enhancements, streamlining usage and offering added convenience.

Durability:

Intrinsic Safety: These dosimeters are crafted to avoid sparking or excessive heat, making them apt for environments with potential explosive or flammable risks.

Data Management:

Warranty: The warranty duration can vary, with longer warranties offering extended assurance and confidence in the product’s longevity.

When choosing a dosimeter both safety factors and long-term financial implications should be taken into account. Consider the following factors when making a choice:

Compliance with Standards: Ensure the dosimeter adheres to pertinent industry standards like ISO or OSHA. This guarantees accurate, reliable measurements and ensures safety protocols are observed.

Measurement Ranges: The dosimeter should be capable of gauging the specific levels and frequencies of physical agents present in your work setting.

System Integration: Look for dosimeters that seamlessly integrate with other monitoring equipment. This is especially crucial if workers utilize multiple monitoring devices.

Warranty: Delve into the warranty details. Understand its duration and scope, particularly for essential components like microphones or sensors.

Technical Support: Evaluate the quality and accessibility of technical support. A responsive support team is invaluable, especially during equipment malfunctions.

The price of a dosimeter can change based on the type of dosimeter and the features and extras that come with it. It is important to note that dosimeters should not be considered standalone units as they may require additional parts, such as calibrators or software features.

Intrinsically safe dosimeters tend to have higher prices due to their advanced construction and the additional certifications required. Dosimeters are often used by large groups of workers and are often sold in packages that include multiple dosimeters and a single calibrator that can be used for multiple dosimeters.

Dosimeters may require verification or calibration certificates from ISO 17025 laboratories, and it is recommended to choose a seller that provides calibration service as it can often be cheaper.

Online shops may offer dosimeters for around $950, but it is not recommended to choose a dosimeter solely based on price.

Professionals often choose ready-to-measure kits that start at around $1.6k USD, as these kits typically include the necessary accessories and features needed for accurate measurements. It is important to consider the total cost of ownership in time, including the cost of any necessary accessories or services when choosing a dosimeter.

Taking a few things into account can help businesses save money on dosimeters without sacrificing quality.

By taking these factors into account, businesses can make informed decisions when purchasing dosimeters that provide high-quality and cost-effective solutions for monitoring physical agents in the workplace.

When using a dosimeter, there are a few best practices to follow to get accurate measurements and keep the work area safe. If you follow these best practices, the dosimeter will be more likely to give accurate readings and keep the work area safe:

When using dosimeter badges, there are a few common problems and limits that should be taken into account. By being aware of these issues and taking appropriate measures to prevent them, dosimeter badges can provide valuable information on the exposure of individuals to physical agents in the workplace:

if the logging feature is not enabled, valuable data on exposure may be lost.

There are several common misconceptions about dosimeters that can lead to misunderstandings about their purpose and effectiveness. It’s important to be aware of these common myths about dosimeters so that you can choose and use them in the workplace in a smart way:

A noise dosimeter is a device that measures the noise exposure of a worker over a period of time and is usually worn on the shoulder. It is designed to meet the accuracy standards set by IEC 61252 for noise dosimeters and IEC 61672 for class 2 sound level meters. These devices are essential for complying with occupational health and safety regulations such as OSHA’s 29 CFR 1910.95 Occupational Noise Exposure Standard or the EU Directive 2003/10/EC.

Noise dosimeters come in two accuracy classes: Class 1 and Class 2. Class 1 devices are more precise and are commonly used in professional settings, while Class 2 devices are suitable for general use.

In addition to accuracy, noise dosimeters can also be classified as either intrinsically safe or non-intrinsically safe. Intrinsically safe devices are specially designed to be used in potentially explosive environments and have safety features that prevent ignition. Non-intrinsically safe devices can be used in less hazardous environments. When choosing a noise dosimeter, it is essential to consider the accuracy class and safety classification that best suits the work environment.

The main reason dosimeters are used in health and safety programs at work is to reduce the chance of being overexposed to noise. Employers have to take action when the risk of being exposed to these dangers is high because of regulations. This can lead to extra costs like buying new equipment, building noise barriers, or putting in place rotation shifts. To avoid these costs, companies should make plans ahead of time and make sure their workplaces meet the rules. This can involve selecting equipment and tools that produce less noise or vibration, which can help reduce exposure levels not just in the workplace but also globally. By implementing a noise policy and using dosimeters to monitor and assess exposure levels, it’s possible to minimize the risk of overexposure and protect the health and safety of workers. This ultimately benefits both employers and employees by reducing healthcare costs, improving productivity, and maintaining regulatory compliance.

Noise dosimeters can be used to measure noise from diverse sources such as machinery, transport, construction, and household appliances. Their primary objective is to assess harmful noise levels that could jeopardize human health, subsequently aiding in the formulation of strategies to reduce these risks.

Predominantly used in professional settings, noise dosimeters are invaluable in environments where individuals face potential harm from excessive noise or vibration. Typical applications include construction sites, factories, airports, and even the entertainment sector—ranging from concert venues to theaters. Additionally, their relevance extends to health care, ensuring ambient noise in hospitals and clinics remains conducive to healing.

Beyond immediate workplace safety, dosimeters have significantly influenced machine design and development. As an integral component of research and development, manufacturers employ them to ensure their products align with regulatory noise and vibration standards. This proactive approach, emphasizing human health during the design phase, not only guarantees safer end products but also underscores the role of dosimeters in advancing occupational health standards.

Dosimeters are an important part of health and safety programs in the workplace that are set up by governing bodies like the European Commission and OSHA in the United States. These programs set guidelines and requirements for the use of dosimeters to measure noise exposure in the workplace. As part of a health and safety program at work, dosimeters can help find potential dangers and figure out how noise and vibration affect workers. It can also help to identify areas where exposure levels exceed established limits and take steps to reduce or eliminate these exposures.

Regular monitoring of exposure levels with dosimeters allows employers to take proactive measures to protect the health and safety of their workers and ensure that they are in compliance with regulatory standards. By following these guidelines and using dosimeters as part of their occupational health and safety programs, employers can take appropriate steps to protect their workers and prevent noise-induced hearing loss.

Noise dosimeters are an important part of health and safety programs at work because they measure noise exposure. Here are some reviews of popular noise dosimeters:

Calibration is an important part of using noise and vibration dosimeters to make sure that the measurements are accurate and reliable.

A calibrated noise dosimeter will give you accurate and reliable measurements, which are important for making sure your workplace is safe and that you are following the rules.

Understanding and addressing these common sources of error can help ensure accurate and reliable noise dosimeter measurements:

To make sure a dosimeter works well and is accurate, it’s important to handle it and care for it in the right way:

Noise dosimeters have a lot of advantages when it comes to measuring noise exposure in real time:

However, there can be limitations to using dosimeters as well:

By understanding the advantages and limitations of using dosimeters, employers can effectively assess noise and vibration exposure in the workplace and take appropriate measures to protect their workers from noise-induced hearing loss.

Proper training is essential to ensure that the results obtained with a dosimeter are accurate and reliable. It’s also important to remember that dosimeters are electronic devices that can be damaged if not handled properly, so it’s important to educate workers about the risks of damage and how to use the device safely in safety zones. By investing in training and education, it’s possible to ensure that dosimeters are used effectively and efficiently to protect the health and safety of workers. Health and safety officers, in particular, need to be trained in the use of dosimeters, including how to set up the device, calibrate it, download and interpret the results and use it safely in hazardous environments. It’s also important to educate workers on the purpose of the measurement and the importance of behaving naturally while using a dosimeter.

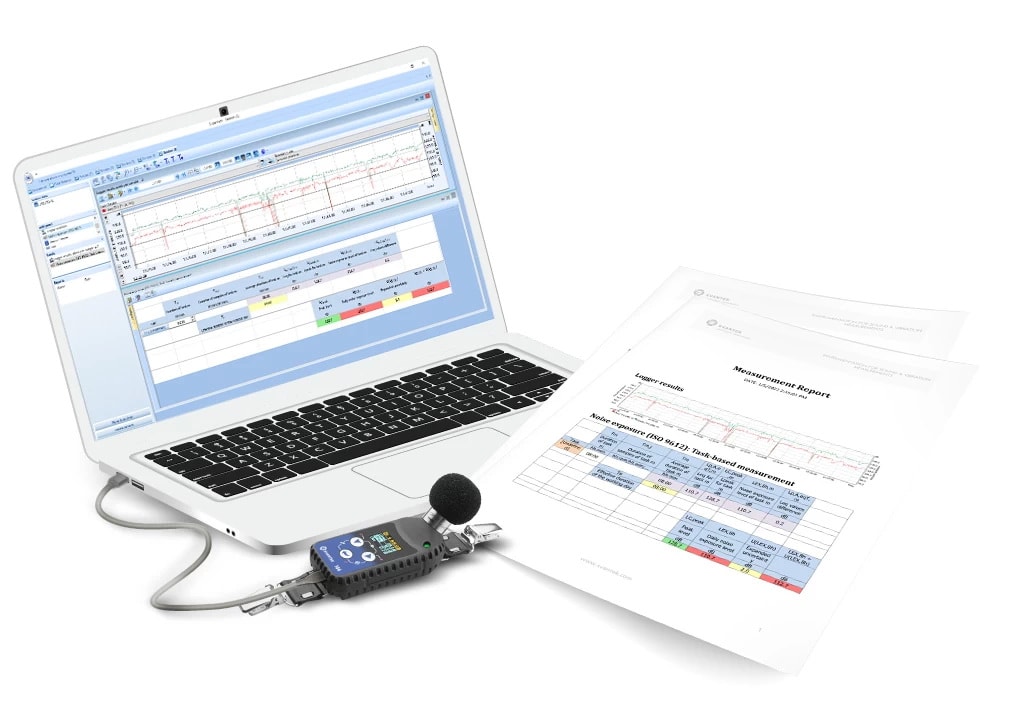

Noise dosimeter software enables measurement data interpretation and provides the ability to integrate various measurements into a single database, which can be organized by worker name. This allows for easy tracking of trends and comparison of results over time. This can be especially important in cases where workers may be making claims for damages due to overexposure or seeking compensation for related injuries. By using software to manage and analyze dosimeter data, it’s possible to more accurately assess the risk of overexposure and take appropriate action to protect the health and safety of workers.

After a measurement is taken with a dosimeter, the results are typically stored in a data file that contains information about the measured noise or vibration levels and the time of the measurements. Most of the time, these results are applied to an 8-hour period and compared to limits that have already been set.

For example, the noise result for an 8-hour period is referred to as a noise dose, which is equivalent to a certain decibel level. Understanding how to interpret and use these results is essential to assessing the impact of noise and vibration on human health and safety. Interpreting dosimeter results involves analyzing the measured noise levels and comparing them to applicable regulatory limits or standards. If the results indicate that noise levels exceed the permissible limits, appropriate measures must be taken to reduce noise exposure and protect workers’ health and safety. Proper interpretation and use of dosimeter results are crucial for maintaining a safe and healthy work environment.

Environmental factors such as temperatures, humidity, and atmospheric pressure conditions impact noise dosimeter accuracy. To ensure accurate and reliable measurements, the dosimeter must be used within its operating range. This is especially important in places like mines, high altitudes, airplanes, spaceships, and ships at sea, where the conditions can be very different from normal workplaces.

Regular noise dosimeter maintenance is important to ensure that the dosimeter is functioning properly. This can involve periodically recharging the battery, checking the sensors, and calibrating the device. By following the manufacturer’s recommendations for maintenance and repair, it’s possible to ensure the accuracy and reliability of the dosimeter over its lifespan. To make sure that dosimeters are properly maintained, it’s important to buy them from a company that offers a warranty and better repair terms. Many companies give a 3-year warranty, which can give you peace of mind and keep you from having to pay for expensive repairs. It’s also a good idea to choose a manufacturer that is certified to offer calibration services. This makes it easier to get the dosimeter calibrated after it’s been fixed and makes sure the measurements are accurate.

Dosimeters are made to be tough and able to handle the demands of the workplace, but accidents or exposure to harsh conditions can still damage them. When this happens, the dosimeter needs to be fixed by the manufacturer or an authorized service center. This is because unauthorized repairs can cause more damage or give wrong readings.

As with any electronic equipment, there are certain safety precautions that should be taken when using dosimeters:

Dosimeters are useful tools for figuring out how much exposure people have to risk factors that can hurt their health. But if there are mistakes in measurements, they may need to be done again, which can take time and cost money. To avoid this, it’s crucial to handle and store dosimeters properly:

Furthermore, it’s worth noting that dosimeters are sophisticated electronic devices that can be expensive to replace if damaged, making it especially important to handle them with care. Proper storage of dosimeters can help ensure that they provide accurate and reliable measurements, saving time and resources while helping to maintain a safe and healthy work environment.

A vibration dosimeter is a personal vibration level meter that measures the vibration exposure of workers. These devices are made to ISO 8041-2 standards and are used to keep track of exposure during the workday, which is usually 8 hours long. Vibration dosimeters can be put into different groups based on how they are meant to be used. For example, some are made to measure hand-arm vibration, while others are made to measure whole-body vibration.

Two types of vibration dosimeters are:

The type of vibration being measured is based on the type of vibration sensor that is used in the dosimeter. Most whole-body vibration sensors measure how fast the seat or platform is moving and how far it is moving, while hand-arm vibration sensors measure how fast the hand or wrist is moving.

Vibration dosimeters are used to measure jobs that involve a lot of vibration, like construction, mining, and operating heavy machinery. As most limits for vibration exposure are set for an 8-hour period, the dosimeter measures the real exposure over the course of the workday. The hand-arm vibration limit for an 8-hour period is referred to as A(8) vibration exposure and is measured in units of acceleration (m/s2).

Both of these vibration dosimeters are made to measure how vibrations affect people’s health and safety. They offer unique features and capabilities that make them suitable for a wide range of applications, from power tool operators to heavy equipment drivers. Employers can protect their workers’ health and safety and make sure they are following regulations by using vibration dosimeter to measure and track exposure levels.

Svantek SV 103 – The SV 103 is a hand-arm vibration dosimeter that meets the latest ISO 8041-2 standard and is designed for measurement in accordance with ISO 5249-2. It features force detection and is recommended for power tool operators who change locations during the workday. The SV 103 can be used in combination with noise dosimeters as it is attached to the arm of the operator. It features a unique function, a MEMS accelerometer integrated with force detection, which makes it an excellent choice for those who require high-precision measurements.

Svantek SV 100A – The SV 100A is a whole-body vibration dosimeter that utilizes a MEMS accelerometer and operator’s presence detector. It is a stand-alone wireless meter placed on the driver’s seat and features remote communication capabilities. It can also track the GPS location of the vehicle. The SV 100A is ideal for use in applications where whole-body vibration exposure is a concern, such as in heavy equipment and transportation industries. The dosimeter meets the latest ISO 8041-2 standard and is designed for measurement in accordance with ISO 2631-1.