Noise monitoring involves long-term sound monitoring without human interaction and can be categorized into workplace monitoring and environmental noise monitoring.

Noise monitoring involves the long-term tracking of sound levels without constant human intervention. There are two primary categories of noise monitoring: workplace noise monitoring and environmental noise monitoring. The distinction between them is based on the location and purpose of the sound source. Among these, environmental noise monitoring is a prevalent form of environmental surveillance, and it is typically conducted using specialized monitoring systems.

Noise monitoring is essential whenever there’s a risk of exceeding established noise level limits. This practice stems from comprehensive studies on the connection between noise and health, leading governments in various countries to set national limit values and regulations for environmental noise.

Noise quality monitoring involves continuously measuring noise levels in an environment to ensure compliance with regulatory limits and minimize health or operational risks. The methods and tools used depend on the application.

Effective monitoring helps prevent hearing damage, reduce noise pollution, and comply with legal standards in various industries

Environmental noise limits vary by region, but common standards set daytime levels around 65 dBA and nighttime levels around 55 dBA for residential and urban areas. Regulatory bodies, such as the World Health Organization (WHO) and national environmental agencies, establish these thresholds to minimize noise pollution and its effects on public health. In high-density urban zones or near industrial sites, stricter or more flexible limits may apply depending on zoning laws and mitigation strategies. Governments enforce these regulations through monitoring stations, noise maps, and legal frameworks, ensuring compliance to protect communities from excessive noise exposure.

In Europe, the directive 2002/49/EC addresses environmental noise pollution, setting guidelines for noise mapping, assessment, and mitigation in urban areas, transport networks, and industrial zones. It does not impose fixed dB limits but requires EU member states to develop noise maps and action plans for areas exposed to excessive noise, typically exceeding 55 dBA at night and 65 dBA during the day. The directive emphasizes long-term noise management, public awareness, and strategic planning to reduce the impact of environmental noise on human health and well-being. Unlike workplace regulations, enforcement is managed by local and national environmental agencies, ensuring that urban planning and transport policies consider noise pollution reduction.

Workplace noise limits focus on occupational safety, with a widely recognized threshold of 85 dBA for an eight-hour work shift before hearing protection is required. Organizations such as OSHA (U.S.), EU-OSHA, and NIOSH define exposure limits to prevent long-term hearing damage in industries with high noise levels, such as manufacturing, construction, and transportation. When noise exceeds safe thresholds, engineering controls, administrative policies, and personal protective equipment (PPE) become mandatory to reduce risks. Employers are responsible for conducting regular noise assessments, providing protective gear, and implementing noise-reduction measures to maintain compliance and safeguard worker health.

In Europe, the directive 2003/10/EC focuses on occupational noise exposure and sets clear action and limit values to protect workers’ hearing. It establishes an upper action value of 85 dBA over an eight-hour period, requiring employers to provide hearing protection and noise reduction measures, and a lower action value of 80 dBA, where hearing protection must be available but not mandatory. The absolute exposure limit of 87 dBA (considering hearing protection) ensures no worker is exposed beyond this threshold. Compliance involves risk assessments, noise reduction strategies, and enforcement by national labor authorities, ensuring a safe working environment in industries such as manufacturing, construction, and transport.

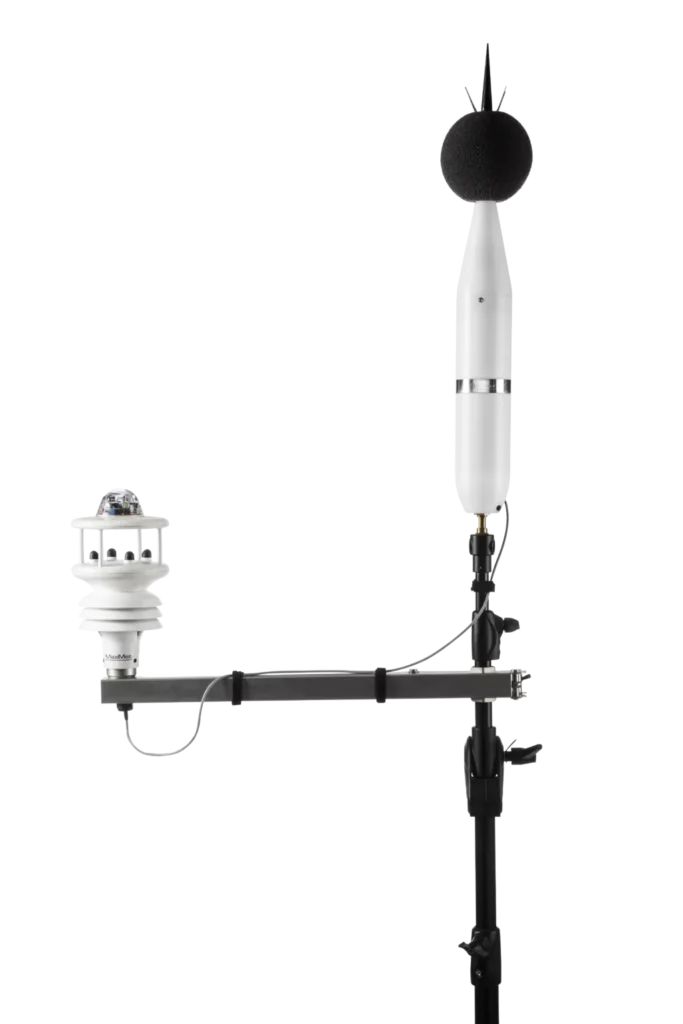

The monitoring system, as outlined in ISO 1996-2, includes a Noise Monitor and a data collection center, along with all the associated hardware and software required for environmental noise monitoring.

The objective of a noise monitor is to provide data regarding the level of noise in a location so that it may be compared to the established noise limits.

A noise monitor is used to measure and evaluate the levels or characteristics of various types of environmental noise. Complying with ISO 1996-2 standards, noise monitors are designed to assess primary noise sources such as road traffic, rail traffic, air traffic, and industrial plants.

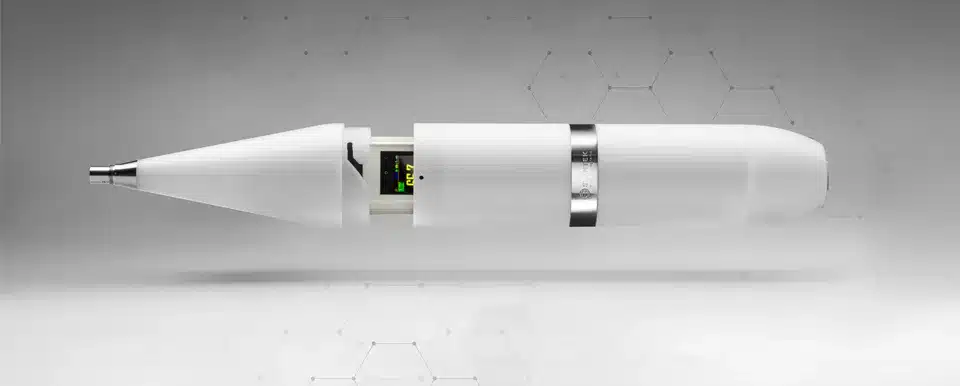

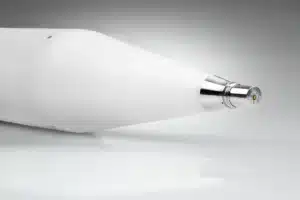

Noise Monitoring Terminal (NMT), is a noise monitor designed for automated, continuous sound monitoring. It measures A-weighted sound pressure levels, their spectra, and relevant meteorological quantities, including wind speed, wind direction, rain, humidity, and atmospheric stability, as outlined in ISO 1996-2:2017.

Class 1 noise monitors adhere to the same performance criteria as Class 1 sound level meters according to IEC 61672. However, while there isn’t a unique standardization exclusively for Noise Monitors, the primary standards guiding their construction and performance are IEC 61672-1, which concerns the instrument’s ability to measure sound levels, and ISO 1996-2, which is tailored for monitoring applications. IEC 61672-1 defines essential performance criteria for these devices, including their linear operating range, directional response, frequency response, and temperature operating range.

There are other considerations tied to measurement applications, such as long-term stability, environmental robustness, powering options, and communication methods. While ISO 1996-2 introduces more criteria, including aspects like GPS functionality, frequency analysis, and the monitoring of meteorological conditions like wind, rain, temperature, and humidity, these specific details won’t be delved into in this article

The microphone class and sound level meter class are often confused with each other. Although the microphone is a removable part (to allow direct insertion of electric test signals), the IEC 61672-1 standard does not specify requirements for a microphone separately. The IEC 61672-1 class performance requirements are applied to a sound level meter with a microphone as a whole. Henceforth, a noise monitor will be considered to satisfy IEC 61672-1 as the entire device, and as a sound level meter with a microphone.

Pattern approval to IEC 61672 ensures the standardization, accuracy, and reliability of noise monitors. It’s an assurance to both manufacturers and end-users that the instrument will perform its intended function correctly and consistently. Pattern approval to IEC 61672 is crucial for noise monitors for several reasons:

Standardization and Consistency: IEC 61672 is a standard set by the International Electrotechnical Commission (IEC) that specifies electro-acoustical performance specifications for sound level meters. Compliance ensures that the noise monitor meets a recognized set of specifications and standards, ensuring consistent and accurate measurements across various instruments and manufacturers.

International Recognition: IEC is an internationally recognized body, and adherence to its standards means that a noise monitor can be trusted and accepted in multiple countries and regions. This facilitates cross-border trade and usage of these devices.

Accuracy and Reliability: The IEC 61672 standard has rigorous requirements for the accuracy and reliability of sound level meters. Having pattern approval means that the noise monitor has been tested and found to meet or exceed these stringent requirements, ensuring that its measurements are reliable and accurate.

Consumer Confidence: For users and consumers of noise monitors, knowing that a device has received pattern approval to IEC 61672 provides confidence in its performance and quality. They can trust that the readings they receive from the monitor are precise and dependable.

Regulatory Compliance: In many jurisdictions, it’s mandatory for noise monitors to comply with specific standards, especially when they’re used in legal or official capacities (e.g., noise pollution checks, workplace noise monitoring). Compliance with IEC 61672 ensures that these devices can be used in such scenarios without legal issues.

Facilitates Comparisons: When different noise monitors conform to the same standard, it allows users to compare their features and performance on a level playing field, ensuring that any differences in readings are due to the devices’ inherent capabilities and not differences in standard adherence.

The origin of MEMS microphones in noise monitoring began with their use in noise dosimetry in 2013. The new-generation MEMS microphones that appeared in 2019 made it possible for them to be utilized in environmental monitoring.

To perform environmental noise monitoring:

Select the appropriate equipment: Depending on the area and purpose of measurement, choose from noise dosimeters, sound level meters, or noise monitors.

Decide on the duration: Determine whether you will be sampling (short-duration measurements) or monitoring (long-duration measurements).

Choose a measurement site:

Follow ISO guidelines: Particularly refer to ISO 1996-2: 2017, which emphasizes the importance of the measurement site selection. The standard states that sites for measuring microphones should be chosen to minimize the effect of residual sound from relevant sound sources.

Begin measurement: Activate the chosen device and let it measure for the predetermined duration, whether sampling or monitoring.

Analyze data: After measurement, analyze the data to determine if noise levels are within acceptable limits or if mitigation actions are needed.

Regularly calibrate and maintain equipment: To ensure accurate and consistent measurements, regularly calibrate your equipment as recommended by the manufacturer and ISO standards.

Document and report: Maintain records of all measurements, analyses, and any actions taken. Depending on local regulations, periodic reporting might be required.

Following the ISO 1996-2, environmental monitoring is done with Noise Monitors placed at a height of 4m in a way to minimize the influence of residual sound from non-relevant sound sources.

Environmental noise monitoring equipment shall meet requirements associated with the measurement application, including long-term stability, environmental robustness, powering, and communication. ISO 1996-2 has additional criteria, such as GPS, frequency analysis, and monitoring of weather conditions (wind, rain, temperature, humidity).

Unattended noise monitoring refers to the process where noise is continuously recorded outdoors for extended periods without the need for human intervention. This means the noise monitor operates independently, capturing data without requiring human attention.

Online noise monitoring is a method of remotely tracking and analyzing noise levels in real-time. As urban areas aim for sustainability and the well-being of their residents, this approach has gained importance. Noise data from the monitoring device is sent to a data collection center using remote communication methods. Platforms like SvanNET offer users access to this online noise monitoring data.

By following these steps and adhering to the ISO 9612 standard, you can effectively monitor and manage noise exposure in the workplace, ensuring the safety and well-being of your employees. To perform noise monitoring at workplace follow these steps:

Refer to the relevant standard: Before starting the noise monitoring process, familiarize yourself with ISO 9612, which provides guidelines for the measurement of noise exposure in the workplace.

Select the appropriate equipment: For workplace noise monitoring, you’ll need a noise dosimeter—a specialized sound level meter designed to measure a worker’s exposure to noise.

Position the microphone: Attach the microphone of the noise dosimeter to the worker’s shoulder. Ensure that it’s placed approximately 10 cm from the ear to capture an accurate representation of the noise the worker is exposed to.

Activate the noise dosimeter: Once the microphone is correctly positioned, turn on the noise dosimeter. Most devices will record data continuously, capturing variations in noise levels throughout the worker’s shift.

Ensure worker compliance: Inform the worker about the purpose of the noise dosimeter and ensure they do not tamper with or remove the device during the monitoring period.

Analyze the data: At the end of the monitoring period (typically at the end of a work shift), download or retrieve the data from the dosimeter. Review the data to determine periods of high noise exposure and calculate the worker’s overall noise dose for the duration.

Take necessary actions: If noise levels exceed permissible exposure limits, take corrective measures. This could include implementing engineering controls, administrative controls, or providing personal protective equipment like earplugs or earmuffs.

Document and review: Maintain a record of all noise measurements, analysis, and actions taken. Regularly review the data to identify trends or areas of concern and ensure compliance with regulations.

Repeat periodically: Noise monitoring should not be a one-time activity. Conduct regular assessments to ensure that workers remain protected from harmful noise levels and that any changes in machinery, processes, or work environment do not result in increased noise exposure.

The future of sound monitoring is poised for transformative advancements, driven in part by the comparable performance of MEMS and classic condenser microphones. MEMS microphones, conforming to the IEC 61672-1 standard, ensure adherence to parameters such as linear operating range, frequency response, directional response, and temperature operating range. As technological developments unfold, newer sound monitors not only measure environmental noise but also offer real-time data analysis, tracing noise trends over extended periods. The integration of machine learning algorithms further allows the creation of sophisticated noise prediction models, identifying potential sound pollution sources and suggesting remediation strategies. Given their cost-effectiveness and exceptional performance, NMT systems equipped with MEMS microphones are emerging as the definitive choice for future multipoint noise monitoring, heralding a more sustainable and harmonious living environment for all.

Micro-Electro-Mechanical Systems (MEMS) microphones represent a significant advancement in noise monitoring for various reasons, and their recognition by esteemed standards bodies further underscores their importance. Here’s a breakdown of why MEMS microphones are considered a milestone in noise monitoring:

Miniaturization and Integration: MEMS microphones are tiny and can be integrated easily into various devices. Their compact size allows for more streamlined and portable monitoring equipment, making them suitable for diverse applications.

Cost-effectiveness: Compared to traditional electret condenser microphones (ECM), MEMS microphones can be manufactured in large quantities at a relatively lower cost. This makes noise monitoring more accessible and widespread.

Consistent Performance: MEMS microphones are manufactured using semiconductor processes, which ensure consistent performance across units. This consistency is vital for accurate noise monitoring.

Durability and Reliability: MEMS microphones have fewer moving parts and can withstand harsh conditions better than their traditional counterparts. This makes them ideal for long-term environmental monitoring.

Digital Capabilities: Many MEMS microphones come with digital interfaces, which can simplify system design and allow for better integration with modern digital systems.

The endorsement by the Physikalisch-Technische Bundesanstalt (PTB) in 2022, granting the world’s first Class 1 Sound Level Meter with a MEMS microphone approval to the SV 307A Noise Monitor, attests to the growing acceptance of MEMS technology in high-precision, standards-compliant applications.

Additionally, the type-approval of the SV 104 noise dosimeter by the Austrian BEV in 2014 marked the beginning of this paradigm shift. The recognition by such standards bodies is a testament to the performance, reliability, and consistency of MEMS microphones, positioning them as viable (or even preferable) alternatives to traditional microphones in noise monitoring applications, both for environmental and workplace settings.

MEMS microphones reduce the cost of the monitoring system without sacrificing performance. The use of MEMS microphones has a very similar effect to that of classic condenser microphones in terms of monitoring systems. As a result, the use of MEMS microphones ensures that parameters such as linear operating range, frequency response, and temperature operating range are conformed to IEC 61672-1.

The appearance of MEMS microphones has shattered the price barrier, on average halving the price of noise monitoring terminals. In addition to NMT cost savings, repair service pricing dropped as well. MEMS microphones are immune to radio frequency interference (RFI) and electromagnetic interference (EMI), as well as environmental resilience. Long-term acoustic monitoring applications in the harsh sub-zero winters and hot, humid summers necessitate this resiliency to changing environmental conditions, which is especially crucial.

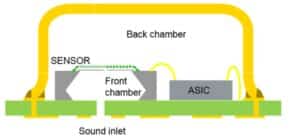

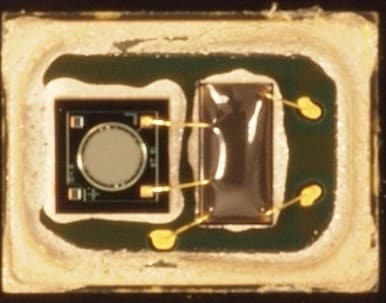

MEMS (Micro Electrical Mechanical System) microphones consist of three main parts: MEMS, ASIC, and package. The MEMS microphone and the ASIC are packaged together in a cavity that is surrounded by a substrate and a lid. A sound inlet (acoustic port) is present either in the substrate or in the lid, and, most of the time, positioned directly in the MEMS cavity.

The MEMS sensor is a silicon capacitor made of two electrically isolated surfaces. One surface, called the backplate, is fixed and covered by an electrode. The other surface, called the diaphragm, is movable and has many holes, that is, acoustic holes.

The other is movable and is called the membrane or diaphragm. A sound wave passing through the acoustic holes of the backplate will set the diaphragm in motion, creating a change of capacitance between the two corresponding surfaces. This is converted into an electrical signal by the Application-Specific Integrated Circuit (ASIC).

The ASIC delivers an analog or digital output, depending on the microphone type.