Noise monitoring in construction refers to the systematic measurement and analysis of noise levels within and surrounding a work site to ensure compliance with legal and safety standards. This practice is part of the British Standard BS 5228-1:2009+A1:2014, which provides a comprehensive code of practice for controlling noise and vibration on construction and open sites.

Noise monitoring in the UK, as per BS 5228 standards, involves automated, long-term tracking of outdoor sound levels, primarily for construction and industrial settings. This type of monitoring is essential for ensuring that noise emissions from construction sites or industrial activities comply with local regulations and do not adversely affect the surrounding environment or communities. Specialized monitoring systems are often employed to capture data, which can then be analyzed for compliance and impact assessment.

In the context of outdoor noise monitoring following BS 5228 standards in the UK, there are several methods employed to track and analyze sound levels:

Continuous Monitoring: Automated systems continuously record noise levels over an extended period, providing a comprehensive dataset for analysis.

Spot Measurements: Short-term measurements are taken at specific locations and times to assess the noise impact during particular activities or phases of a project.

Long-term Averaging: Noise levels are averaged over a specified duration, such as a day or a week, to evaluate compliance with regulatory limits.

Peak Noise Monitoring: This method focuses on capturing and analyzing the highest levels of noise generated, often crucial for activities known to produce sudden, loud noises.

Frequency Analysis: This involves breaking down the noise into its frequency components to identify specific noise sources and their characteristics.

Real-time Monitoring: Some advanced systems offer real-time data transmission and alerts, enabling immediate action if noise levels exceed predetermined thresholds.

Remote Monitoring: Noise monitoring equipment can often be accessed and controlled remotely, allowing for adjustments to be made without having to physically visit the site.

Data Logging: All the captured noise data is logged and stored for future reference, compliance verification, and impact assessment.

These methods can be used individually or in combination, depending on the specific requirements of the project and the regulatory framework in place.

In the UK, there is no single set of dB limits for environmental noise that applies universally. Regulations and guidelines can vary depending on the source of the noise, the location, and the time of day. However, for construction activities, the document BS 5228-1:2009 suggests that noise levels should not exceed 70 dBA in rural, suburban, and urban areas away from main roads and 75 dBA in urban areas near main roads between 07:00 and 19:00 hours. For long-term earth-moving activities, a limit of 55 dB Laeq, 1 h is suggested for daytime construction noise, provided the works are likely to occur for a period exceeding six months.

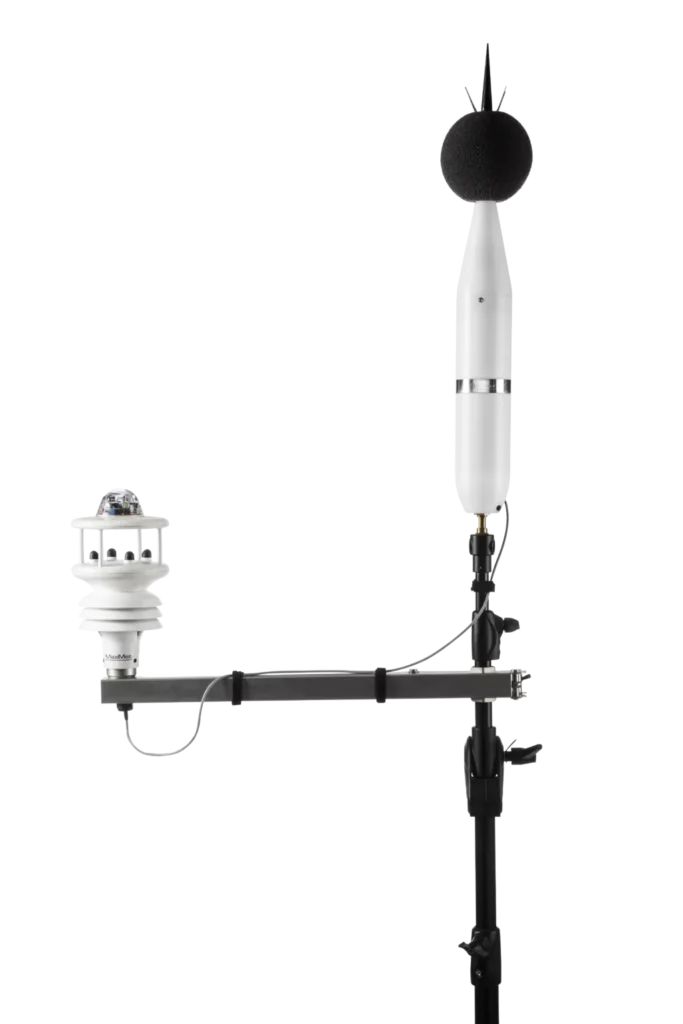

A noise monitoring device is a specialized instrument designed to measure and record environmental noise levels over a period of time. It adheres to ISO 1996-2 standards and includes a Noise Monitor and a data collection center, along with the necessary hardware and software for environmental noise monitoring. The primary objective of a noise monitor is to collect data on noise levels in a specific location, allowing for comparison with established noise limits.

The term “Noise Monitoring Terminal (NMT)” refers to a noise monitor specifically designed for automated, continuous sound monitoring. It not only measures A-weighted sound pressure levels but also captures relevant meteorological data like wind speed and direction, rain, humidity, and atmospheric stability. The difference between a Class 1 noise monitor and a Class 1 sound level meter lies in their application and additional functionalities. While both adhere to BS EN 61672-1 standard for measuring sound levels, a Class 1 noise monitor also follows ISO 1996-2 guidelines, which include additional criteria like GPS functionality, frequency analysis, and meteorological monitoring. These additional features make noise monitors more suited for long-term, comprehensive noise assessment.

Class 1 noise monitors adhere to the same performance criteria as Class 1 sound level meters according to IEC 61672. However, while there isn’t a unique standardization exclusively for Noise Monitors, the primary standards guiding their construction and performance are IEC 61672-1, which concerns the instrument’s ability to measure sound levels, and ISO 1996-2, which is tailored for monitoring applications. IEC 61672-1 defines essential performance criteria for these devices, including their linear operating range, directional response, frequency response, and temperature operating range.

There are other considerations tied to measurement applications, such as long-term stability, environmental robustness, powering options, and communication methods. While ISO 1996-2 introduces more criteria, including aspects like GPS functionality, frequency analysis, and the monitoring of meteorological conditions like wind, rain, temperature, and humidity, these specific details won’t be delved into in this article

Pattern approval to IEC 61672 is crucial for noise monitors because it ensures that the devices meet internationally recognized standards for accuracy, reliability, and consistency. Compliance with this standard facilitates the device’s acceptance across various countries and regions, boosting consumer confidence and enabling its use in regulatory contexts. The IEC 61672 standard sets rigorous performance specifications for sound level meters, and having pattern approval means the noise monitor has been tested and verified to meet these stringent requirements. This not only ensures the reliability and accuracy of the device but also makes it easier for users to compare different noise monitors on a level playing field.

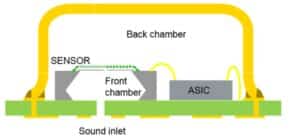

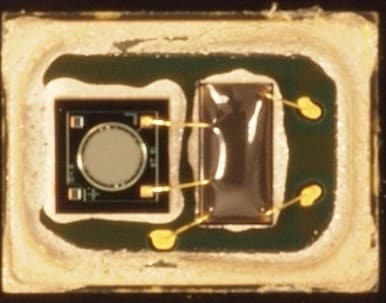

A MEMS (Micro-Electro-Mechanical Systems) microphone is a compact, cost-effective, and highly reliable device used for capturing sound. It consists of a silicon diaphragm and backplate that form a capacitor. Sound waves cause the diaphragm to move, changing the capacitance, which is then converted into an electrical signal by an Application-Specific Integrated Circuit (ASIC).

MEMS microphones are considered a milestone in noise monitoring for several reasons:

Miniaturization: Their small size allows for easy integration into various devices and applications, making noise monitoring more versatile and portable.

Cost-Effectiveness: These microphones can be mass-produced at a lower cost compared to traditional microphones, making noise monitoring more accessible.

Consistency: The semiconductor manufacturing processes used for MEMS microphones ensure uniform performance, crucial for accurate noise monitoring.

Durability: With fewer moving parts and a robust design, MEMS microphones are more durable and can withstand harsh environmental conditions, making them ideal for long-term monitoring.

Digital Capabilities: Many MEMS microphones offer digital outputs, simplifying system design and allowing seamless integration with modern digital systems.

The technology has gained recognition from standards bodies like the Physikalisch-Technische Bundesanstalt (PTB) and the Austrian BEV, affirming their suitability for high-precision, standards-compliant applications in both environmental and workplace noise monitoring.

The origin of MEMS microphones in noise monitoring can be traced back to their initial use in noise dosimetry around 2013. Advances in the technology by 2019 enabled their application in broader environmental noise monitoring.

The microphone class and sound level meter class are often confused with each other. Although the microphone is a removable part (to allow direct insertion of electric test signals), the BS EN 61672-1 standard does not specify requirements for a microphone separately. The BS EN 61672-1 class performance requirements are applied to a sound level meter with a microphone as a whole.

Henceforth, a noise monitor will be considered to satisfy BS EN 61672-1 as the entire device, and as a sound level meter with a microphone.

To conduct environmental noise monitoring, one starts by selecting the appropriate equipment, such as noise dosimeters, sound level meters, or noise monitors, based on the area and purpose of the measurement. The duration of the measurement, either short-term sampling or long-term monitoring, must be decided. The measurement site should be carefully chosen to represent the noise sources in question and installed according to ISO procedures, particularly ISO 1996-2:2017.

Once the equipment is set up, measurements are taken for the predetermined duration. The data collected is then analyzed to determine if noise levels are within acceptable limits or if mitigation actions are required. Regular calibration and maintenance of the equipment are essential for accurate results. All measurements, analyses, and actions taken should be documented, and depending on local regulations, periodic reporting may be necessary.

The noise monitor should be located at a height of 4 meters, as per ISO 1996-2, to minimize the influence of residual sound from non-relevant sources. The equipment used should meet various requirements, including long-term stability, environmental robustness, and powering options. ISO 1996-2 also specifies additional criteria like GPS functionality, frequency analysis, and weather condition monitoring.

Unattended noise monitoring refers to the autonomous recording of noise levels outdoors for extended periods, without human intervention. Online noise monitoring allows for the remote tracking and analysis of noise levels in real-time, which is increasingly important for urban sustainability. Data from the noise monitor is sent to a data collection center using remote communication methods, and platforms like SvanNET provide access to this data.

The British Standard BS 5228-1:2009+A1:2014 outlines a comprehensive procedure for estimating noise levels from construction sites. It emphasizes the importance of predicting expected noise levels for various stakeholders, including local authorities, developers, architects, engineers, and contractors. The standard provides a systematic approach to noise estimation, taking into account factors such as the sound power outputs of processes and plant, periods of operation, distances from sources to receiver, and the presence of screening by barriers, among others.

The standard offers methods for calculating noise levels, primarily focusing on the equivalent continuous sound level (Laeq). It suggests three main ways to obtain the necessary data for the source noise level: direct measurements, using sound power levels and values of activity Laeq given in annexes, or obtaining the maximum permitted sound power level under EC directive 2000/14/EC.

The standard also provides a detailed method known as the “activity Laeq method” for both stationary and quasi-stationary activities. This method involves multiple stages, from obtaining an activity Laeq to making allowances for reflections and screening. It also includes procedures for adjusting the Laeq for the assessment period and for different ground conditions (hard, soft, or mixed).

The standard acknowledges that other factors like meteorological conditions can also influence noise levels but states that the estimation of these effects is beyond its scope. Overall, the standard aims to provide a robust and systematic approach to noise estimation, facilitating better planning and management of noise in construction sites.