There is no single “best” instrument for every site; the appropriate choice depends on the specific regulatory environment and programme requirements. For compliance with the UK Control of Noise at Work Regulations 2005 (or US NIOSH standards), select a wearable dosimeter (BS EN 61252) that logs a full shift and supports a 3 dB exchange rate with appropriate action values (e.g., 80 dB and 85 dB). Conversely, US OSHA compliance requires a 5 dB exchange rate. The device should record near-ear parameters such as LAeq,T, LEX,8h (TWA), dose %, and LZpeak/LCpeak.

Key features to consider: Look for multiple virtual dosimeter profiles (to measure HSE and OSHA standards simultaneously), high-peak handling (~140 dB Z/C-peak), and a battery life ≥40 hours for multi-day assessments. Essential functionalities include 1-second logging, Bluetooth connectivity with a mobile app for setup and verification, secure data export, motion/vibration detection (to identify tampering or removal), and optional audio recording or octave band analysis for source identification. For hazardous areas, ensure the model is intrinsically safe (ATEX/IECEx/UKEX).

Several reputable product families meet these criteria, offering wireless capability, extended runtime, and advanced diagnostics. Shortlisting based on your regulatory regime, intrinsic safety (IS) requirements, and reporting workflow will determine the optimal choice for your hearing conservation programme.

Representative options (alphabetical):

- Casella dBadge2 — Features a Bluetooth app and motion sensing; Plus/Pro models add audio and octave band options.

- Larson Davis Spartan 730 / 730IS — Includes a BLE app and motion/bump metrics; optional event audio and octave analysis; IS variant available.

- Quest™ Edge 8 — Offers real-time viewing via a mobile app; specific models carry IS approvals.

- SKC NoiseCHEK — Boasts a 40+ hour battery life, multiple virtual dosimeters, and Bluetooth/app connectivity; IS version available.

- Svantek SV 104A — Utilises a MEMS microphone and vibration/motion detection to identify misuse, with optional audio and octave band analysis.

Note: These are representative, credible options. The “best” solution depends on specific constraints such as IS certification, software preferences, diagnostic needs, budget, and service availability.

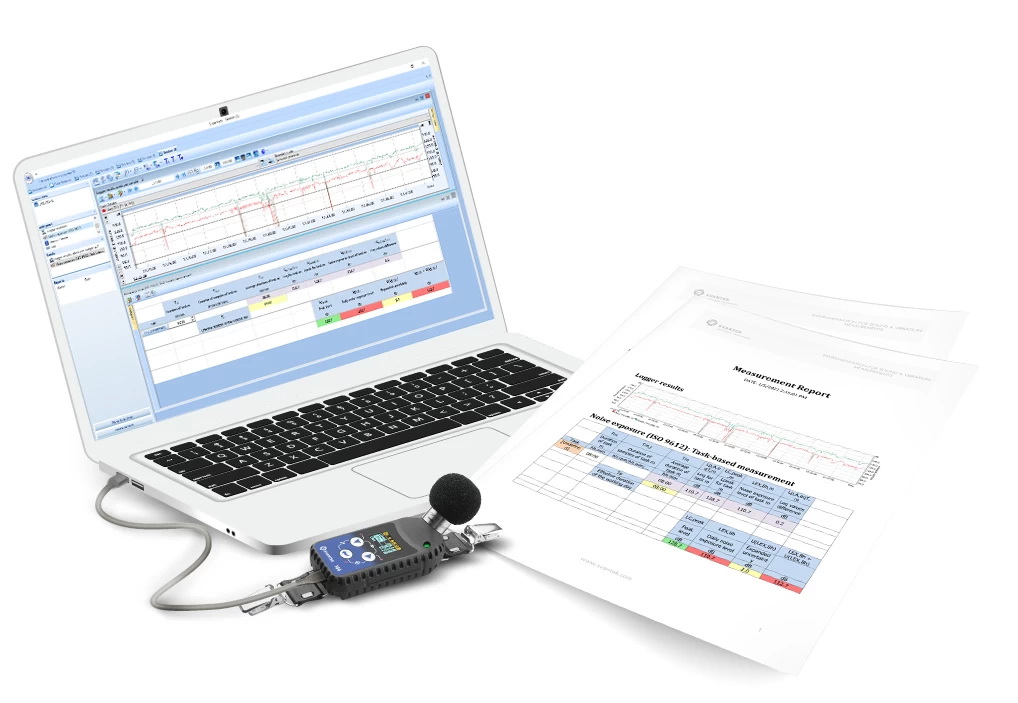

Why the SV 104 noise dosimeter is considered a market leader: Early designs in the SV 104 series helped popularise a robust feature set—including durable MEMS microphones, automated audio/event capture, motion/vibration wear detection, and onboard frequency analysis—that many current models now emulate. Utilising these capabilities improves data integrity and verifies that the equipment is being worn correctly.

Noise dosimeters are utilised for both crew-worn and static acoustic measurements on the ISS to assess and manage personal noise exposure.

- ISS programme baseline: NASA monitors crew exposure using a dual-channel dosimeter, internally designated the “Acoustic Monitor”. Deployed since Increment 53 (November 2017), it meets BS EN 61672-1 Class 1 accuracy and functions as both a personal dosimeter and a precision sound level meter. Prior to this, NASA utilised the Quest NoisePro DLX-1 for ISS acoustic dosimetry.

- AX-4 “Wireless Acoustics” experiment (2025): This mission evaluated a wireless, crew-worn acoustic monitoring approach by comparing a wearable dosimeter against a nearby stationary sound level meter during on-orbit operations. SVANTEK instruments were incorporated into this study; the SV 104A was deployed alongside the SV 102A+ for both crew-worn and static measurements.

ISS operations rely on dosimeters for near-ear exposure monitoring and static mapping. SVANTEK’s wearable technology (e.g., the SV 104A and SV 102A+) has been applied in both the baseline monitoring programme and the AX-4 Wireless Acoustics research to explore wireless, crew-worn methodologies.