Vibration Monitoring Applications in Construction

Vibration monitoring in construction primarily focuses on managing ground vibration, which encompasses a variety of sources and impacts. These applications highlight the critical need for precise monitoring and control to safeguard structures and ensure the safety and comfort of individuals in affected areas.

Blasting Vibration: This type of ground-borne vibration, with a frequency range of 1-300 Hz and peak particle velocity (PPV) values up to 50 mm/s, can significantly affect structures, particularly those with frequency content around 6-10 Hz. Additionally, the air overpressure generated by explosions, with low frequencies up to 40 Hz, can damage windows and facades of buildings.

Pile Driving Vibration: Generated during pile driving operations, these signals have a frequency range of 1 to 100 Hz and can reach PPV values up to 100 mm/s. They are particularly dangerous at low frequencies around 20 Hz, posing risks to nearby structures.

Concrete Crunchers and Rock Machinery: These operate at lower frequencies, around 3 Hz for concrete crunchers, with rock machinery producing ground vibrations in the range of 1-100 Hz and PPV up to 100 mm/s. Such equipment can affect both the construction site and surrounding areas.

Construction Work Inside Buildings: Activities within buildings can generate vibrations ranging from 1-300 Hz with PPV up to 30 mm/s, which can be hazardous to the construction itself and its immediate surroundings.

Heavy Trucks: The movement of heavy trucks to and from the site produces low-frequency vibrations (1-100 Hz) with PPV values that can reach up to 50 mm/s. This type of signal is especially concerning for roads, infrastructure, and nearby buildings.

The Importance of Real-Time Analysis in Construction Activities

The real-time analysis of vibrations in construction activities is a critical process that ensures the immediate assessment of vibration amplitude and dominant frequency directly within the monitoring equipment. This capability allows for an on-the-spot comparison of recorded signals against predefined limits. When amplitudes exceed these limits, the system can trigger alerts through various means such as SMS, email, or visual and auditory alarms, prompting immediate action to halt construction activities and prevent potential damage to surrounding structures.

Implementing such online analysis systems is technologically demanding, requiring significant computational power and accuracy. This is because halting construction work unnecessarily can lead to substantial costs of downtime for construction companies. Therefore, precision in predictive maintenance and analysis is paramount to avoid false alarms that could disrupt the construction schedule without cause.

To enhance reliability and minimize false positives, vibration monitoring is often conducted at multiple points, both at the vibration source and at buildings or structures deemed at risk. This multi-point monitoring approach helps to verify whether vibrations are indeed propagating along expected paths and can identify if a sensor has been accidentally disturbed by construction workers. If one monitor triggers an alarm but others do not detect similar waves, it may indicate a false alarm, allowing work to continue without interruption. This method of cross-checking ensures that construction activities are only stopped for legitimate concerns, balancing the need for structural safety with the economic implications of work stoppages.

Types of Vibration Monitors and Sensors

In building and construction vibration, the selection of appropriate monitors and sensors is crucial for the accurate assessment of vibratory motion. These devices are broadly divided into two main categories, each with distinct operational principles and suited for specific applications within the construction industry:

Velocity Transducers (Geophones): These electromagnetic devices are widely utilized for structural vibration measurements. Operating effectively at frequencies above their natural frequency, geophones are particularly valuable for evaluating the impact on buildings and other structures. Their ability to measure vibration velocity makes them indispensable in assessing the potential damage to structures caused by construction activities.

Piezoelectric Accelerometers: Designed to measure acceleration, these sensors operate below their natural frequency and are known for their high sensitivity. This makes them versatile for a broad spectrum of applications, from detailed engineering analysis to monitoring during construction processes. Piezoelectric accelerometers are essential for capturing the full spectrum of vibratory motion, providing critical data for safeguarding structural integrity.

The choice between these sensors hinges on the specific needs of the monitoring application, including the frequency and amplitude range, the measurement environment, and the required precision of the analysis. Standards such as ISO 4866:2010 and DIN 45669-1 categorize vibration data collection systems and instrumentation based on their ability to define complex motion and their application scope, ranging from high-precision engineering analysis (Class 1) to general field monitoring (Class 2), with subclasses for specialized applications. The detection limit and operating frequency range of the equipment are tailored to ensure sensitivity and accuracy, extending from 1 Hz to 80 Hz for general applications, and up to 500 Hz adjusting to accommodate specific frequencies encountered in construction near railway traffic routes.

Overview of Monitoring Technologies

In the construction industry, the choice of monitoring technologies is determined by the specific needs of each project, with a variety of sensors deployed to measure vibrations and ensure structural integrity. These sensors are strategically placed, often on building walls or foundations, to capture accurate data on vibratory movements. The method of data transmission from these sensors varies: underground or foundation-attached sensors typically rely on wired connections due to signal penetration issues, while outdoor monitors utilize GSM antennas for wireless communication, enabling SMS alerts and internet-based data sharing.

For projects requiring monitoring over extensive areas, such as bridges, optical sensors are employed for their precision in remote vibration detection. Although highly accurate, the implementation of wireless vibration optical sensors is considerably more costly, making them a less common choice reserved for situations where their advanced capabilities are necessary. This adaptability in monitoring technologies ensures that construction projects can maintain real-time oversight of structural conditions, adapting to the unique challenges presented by different environments and project scopes.

Remote Vibration Monitoring Equipment

Remote vibration monitoring equipment is designed to ensure the continuous surveillance of structural integrity from a distance, functioning through two primary operational modes. The first mode involves conducting the analysis directly within the monitor itself, after which data and alarms are sent to the relevant parties via a modem. This method is particularly favored in construction settings due to its reliability and the swift reaction times it offers, enabling immediate responses to potential structural issues.

The second mode involves the transmission of raw data to a cloud server, where the analysis is then carried out. While this method centralizes data processing and can offer advanced analytical capabilities, the direct analysis mode within the monitor is preferred for its efficiency and dependability in critical construction environments. To facilitate these operations, various communication technologies are employed based on the location and specific requirements of the monitoring setup: LTE (4G) modems are commonly used in open areas for their wide coverage, whereas WiFi and LAN connections are preferred in enclosed spaces such as tunnels and indoor settings, ensuring that the remote vibration monitoring equipment remains connected and operational regardless of the project’s environment.

How to Monitor Construction Vibration

Monitoring construction vibration effectively requires adherence to a chosen standard method, which dictates the specific procedures to follow. The foundational steps involve selecting the appropriate equipment, strategically mounting this equipment in alignment with the vibration’s propagation path, and ensuring a secure coupling of sensors to the surface to accurately capture vibratory data. Modern systems simplify the process of monitoring against predefined limits, yet thorough analysis of time history data remains essential for a deep understanding of the signal characteristics and their potential impact on structures.

Calibration of the equipment is a critical step to verify that sensors are functioning correctly and providing accurate measurements. This ensures the reliability of the data collected and the assessments made based on this data, safeguarding against false readings that could lead to incorrect conclusions about structural safety or the necessity of mitigation measures.

Pre-construction surveys serve as a preliminary assessment phase, conducted before the commencement of construction activities. These surveys aim to evaluate the existing vibration patterns, such as those from nearby railway operations, and their potential impact on the planned structures. Additionally, they help establish a baseline vibration background, against which the effects of construction-induced vibrations can be measured. Measurements during this phase are typically performed directly in the ground along the expected transmission paths and on the foundation plate once it is constructed. This initial evaluation is crucial for understanding the site’s pre-existing conditions and for planning construction activities in a manner that minimizes adverse effects on the surrounding environment and structures.

Monitoring Noise and Dust in Construction Sites

In addition to vibration, construction activities often generate significant levels of noise and dust, which can have adverse effects on the environment and human health. Consequently, vibration monitoring programs employing these elements are an integral part of the overall management of construction sites, ensuring that harmful emissions are kept within the limits set by local regulations. Monitoring systems for construction sites typically encompass noise and dust measurements, alongside vibration analysis, to provide a comprehensive overview of the site’s environmental impact.

The accuracy and relevance of noise and dust monitoring are influenced by various factors, including wind speed and direction, which can significantly affect the dispersion of dust and the propagation of noise. To account for these variables, weather monitoring is frequently incorporated into the assessment process. This holistic approach enables construction managers to implement timely and effective mitigation strategies, such as adjusting work schedules, employing dust suppression techniques, or installing noise barriers, to minimize the environmental footprint of their projects. By adhering to local emission regulations through diligent monitoring and management of noise, dust, and vibration, construction projects can reduce their impact on surrounding communities and the environment, fostering safer and more sustainable construction practices.

How to Analyze Vibration Levels

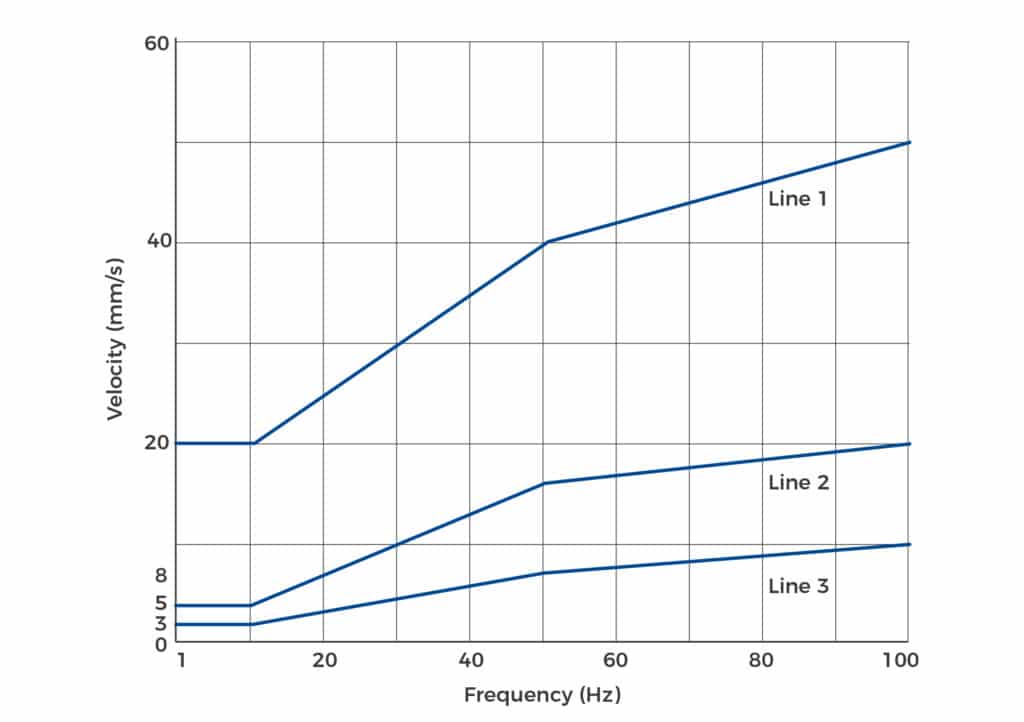

Analyzing vibration levels in construction and structural engineering involves adhering to specific standards that guide the measurement and evaluation of effects on structures. Among the most recognized is the German standard DIN 4150-3, which, along with the international standard ISO 4866, sets forth methodologies for assessing vibration impact. These standards are particularly applicable to structures without specific dynamic load design requirements, outlining level values to prevent damage and impact. DIN 4150-3 categorizes vibrations into short-term, which are infrequent enough not to cause fatigue or resonance, and long-term, encompassing all other types. It provides a framework for assessing the impact of short-term vibrations by dividing structures into three categories, each with a corresponding permissible vibration velocity limit, facilitating a clear understanding of their impact on various structures.

For long-term vibrations, DIN 4150-3 establishes limit values for velocity, aiding in the protection of structures and their occupants from potential harm. Similarly, the British Standard BS 7385-2 offers guidance on assessing vibration-induced damage risks from various sources, including construction activities and traffic, focusing on direct vibration effects on buildings. In the United States, the vibration criterion (VC) curves developed by the Institute of Environmental Sciences and Technology (IEST) provide a basis for designing facilities housing vibration-sensitive instruments, using root-mean-square (RMS) velocity expressed in one-third octave bands. These standards collectively underscore the importance of a methodical approach to analysis, ensuring the structural integrity and safety of buildings in the face of diverse sources.

Utilizing Vibration Level Charts for Analysis

Standards such as DIN, BS, or IEST present limits in the form of vibration level charts, which serve as a crucial tool in the analysis of construction-related vibrations. These charts allow for the plotting of time history data from vibration monitoring points, offering a visual means to identify when and where measured levels exceed the set limits. This graphical representation simplifies the task of pinpointing exceedance events, often with features that enable users to navigate directly to specific events of interest with a simple click.

The ability to visually track abnormal vibration amplitudes against standardized limits not only aids in immediate analysis but also facilitates the generation of detailed reports for individual events. These reports are essential for compliance purposes, providing documented evidence that construction activities are being monitored and managed by the relevant standards. By utilizing limit-level charts for analysis, stakeholders can ensure a more efficient and effective approach to maintaining structural integrity and adhering to regulatory requirements, thereby minimizing the potential impact of construction on the surrounding environment.

Understanding PPV, RMS, and VDV

Understanding the metrics used to evaluate vibration impacts is crucial for both structural integrity and human comfort. Peak Particle Velocity (PPV) is commonly employed for assessing vibrations in structures and the ground, focusing on the velocity of waves. This measurement is pivotal for evaluating the potential damage to buildings and infrastructure caused by construction activities.

When it comes to assessing the impact of vibrations on humans within buildings, the focus shifts to vibration acceleration, which provides a more accurate representation of how the transmitted energy affects human comfort and health. Measurements of acceleration are often conducted using the same equipment as for PPV but are placed in different locations, such as the middle of floors where people work or live, or near workstations to assess floor vibrations more accurately. For these human-centric assessments, metrics like Root Mean Square (RMS) and Vibration Dose Value (VDV) are utilized. RMS offers an average level of vibration energy over time, making it suitable for continuous monitoring, while VDV provides a cumulative measure of vibration exposure, capturing both the intensity and duration of vibrations. These metrics are essential for ensuring that levels remain within acceptable limits to prevent discomfort or health issues for individuals in vibrated environments.