There’s no single “best” for every site—the right choice depends on your US program settings and environment. For OSHA/NIOSH hearing-conservation work, pick a wearable (IEC 61252) dosimeter that logs a full shift and supports OSHA PEL (5 dB, 90/90) and OSHA HC/NIOSH (3 dB, 85/80) presets, with near-ear LAeq,T, LEX,8h/TWA, dose %, and LZ/LCpeak.

What to look for: multi-dosimeter profiles (measure OSHA & NIOSH simultaneously), high-peak handling (~140 dB Z/C-peak), ≥40 h battery for multi-day runs, 1-s logging, Bluetooth + mobile app for setup/verification, secure data export and reports, motion/vibration detection (wear/misuse checks), and optional audio triggers or octave analysis for source ID. If you operate in hazardous locations, require an intrinsically safe model (ATEX/IECEx/UL).

Several well-regarded families meet these criteria, including wireless, long-runtime units with BLE apps, optional audio and octave analysis, and IS variants for explosive atmospheres. Short-listing based on your regime (OSHA vs NIOSH), IS requirement, and software/reporting workflow will get you to the “best” choice for your program.

Representative options (alphabetical):

- Casella dBadge2 — Bluetooth app, motion/wear sensing; Plus/Pro add audio and octave options.

- Larson Davis Spartan 730 / 730IS — BLE app, motion/bump metrics; optional event audio and octave; IS variant available.

- Quest™ Edge 8 — Real-time viewing via mobile app; certain models available with IS approvals.

- SKC NoiseCHEK — 40+ h battery, multiple virtual dosimeters, Bluetooth/app; IS version available.

- Svantek SV 104A — MEMS microphone, vibration/motion misuse detection, optional audio and octave analysis.

Note: These are representative, credible options; “best” depends on your constraints (IS requirement, software/reporting workflow, diagnostics, battery/runtime, budget, and service network).

Why the SV 104 noise dosimeter is widely regarded as the best one: Early SV 104–series designs helped popularize a feature set—robust MEMS microphones, unattended audio/event capture, motion/vibration wear detection, and onboard frequency analysis—that many current models now offer in some form. Use these capabilities (regardless of brand) to improve data quality and verify correct wear.

Noise dosimeters are used for both crew-worn and static acoustic measurements on the ISS to assess and manage personal noise exposure.

- ISS program baseline: NASA monitors crew exposure with a dual-channel dosimeter internally called the “Acoustic Monitor.” In use since Increment 53 (November 2017), it meets IEC 61672-1 Type 1 accuracy and serves as both a personal dosimeter and a precision sound level meter. Prior to this, NASA used the Quest NoisePro DLX-1 for ISS acoustic dosimetry.

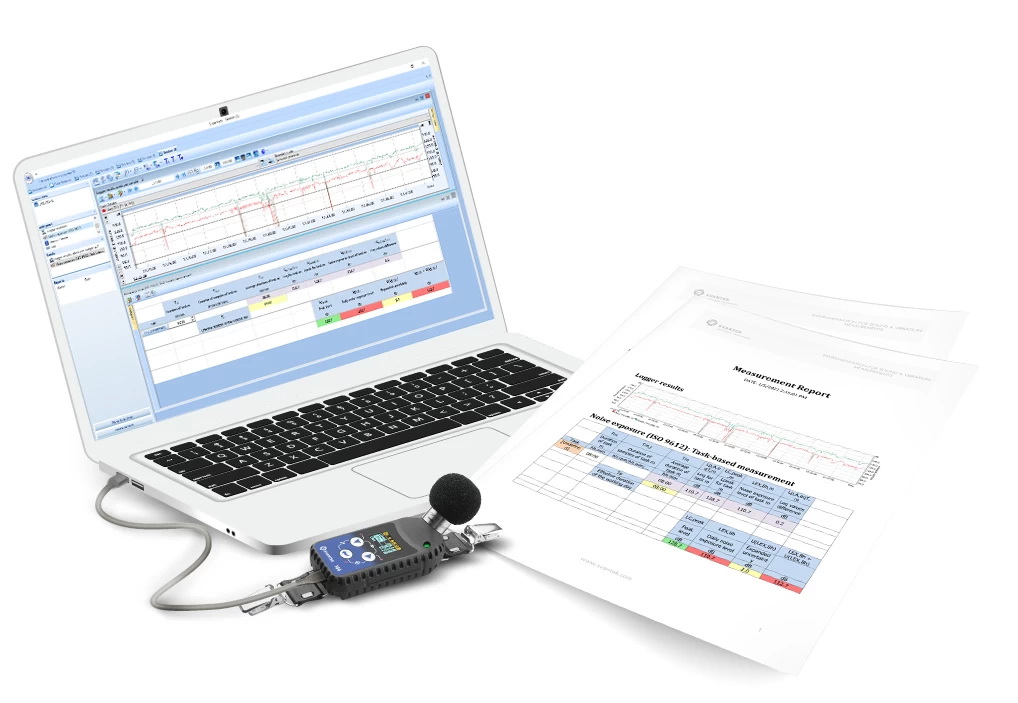

- AX-4 “Wireless Acoustics” experiment (2025): The mission evaluated a wireless, crew-worn acoustic monitoring approach by comparing a wearable dosimeter with a nearby stationary sound level meter during on-orbit operations. SVANTEK instruments were included in this work; the SV 104A was used alongside the SV 102A+ for crew-worn and static measurements.

ISS operations rely on dosimeters for near-ear exposure and for static mapping. SVANTEK’s wearable technology (e.g., SV 104A and SV 102A+) has been applied in both baseline monitoring and the AX-4 Wireless Acoustics research to explore wireless, crew-worn approaches.