How do different sources of impact the severity and nature of the vibrations experienced?

The source plays a crucial role in determining the severity and nature of the vibrations experienced, impacting structures, machinery, and even human well-being in various ways.

- Natural sources, such as earthquakes and wind, can produce vibrations with a wide range of severity—from barely noticeable to devastatingly intense—and frequencies that are often unpredictable and varied. Earthquake vibrations, for instance, are sudden and random, capable of causing significant structural damage, while wind-induced vibrations may cause continuous but variable stress on buildings and bridges.

- Man-made vibrations, generated by machines, vehicles, and human activities, tend to have a more predictable and repetitive nature, with their severity closely linked to the operational intensity of the source. For example, industrial machinery can produce sustained vibrations that may affect the structural integrity of nearby buildings over time, while the intermittent vibrations from human activities, though generally less severe, can disrupt sensitive operations in environments like hospitals or laboratories.

The duration of vibration exposure—short-term impacts like explosions versus long-term effects from continuous machinery operation—further influences the potential for damage or discomfort. Ultimately, understanding the specific characteristics of vibrations from different sources enables more effective management of their impacts, enhancing safety, comfort, and operational reliability across a wide range of contexts.

What are the primary parameters used to describe vibration?

The primary parameters to describe the vibration are displacement, velocity, and acceleration. Velocity or acceleration parameters are often favoured because they tend to produce a flatter frequency spectrum, which helps in utilizing the dynamic range of the instrumentation better than displacement measurements.

Acceleration measurements are particularly useful where the range of interest includes high frequencies, as acceleration tends to be weighted towards these components.

Displacement measurements are of limited value in general vibration analysis because appreciable displacements typically only occur at low frequencies, whereas mechanical systems may exhibit important characteristics at a wider range of frequencies.

Can the parameters of vibration be converted to each other?

Yes, the parameters can be converted between each other. For sinusoidal signals, velocity can be obtained by dividing the acceleration by a frequency-proportional factor, and displacement can be obtained by dividing the acceleration by a factor proportional to the square of the frequency. This mathematical conversion is usually performed by electronic integrators in the measuring instruments.

What units are typically used to measure vibration parameters?

Vibration parameters are almost universally measured in metric units (e.g. mm, mm/s2, mm/s) in accordance with ISO requirements. The gravitational constant “g” is also used for acceleration levels, and it relates to the metric system by a factor of approximately 9.81, allowing for easy mental conversion.

Why is the RMS value considered the most relevant measure of vibration amplitude?

The RMS (Root Mean Square) value is the most relevant measure because it incorporates the time history of the vibration and correlates directly with the energy content. This makes it a critical measure for assessing the destructive potential of the vibration.

Since the RMS value is directly related to the energy, it can be used to gauge the potential for damage or destruction. Higher RMS values typically indicate more energy, which can lead to greater wear, fatigue, or failure of materials and structures subjected to the vibration.

What is the peak and peak to peak?

The peak value is crucial for characterizing the highest level of short-duration shocks or transient forces in a vibration signal.

The peak-to-peak value represents the maximum extent of the wave’s motion, from the highest to the lowest point. It is particularly important when the maximum displacement of a machine part is critical for assessing maximum stress or ensuring mechanical clearances are not exceeded.

What is a spectrogram?

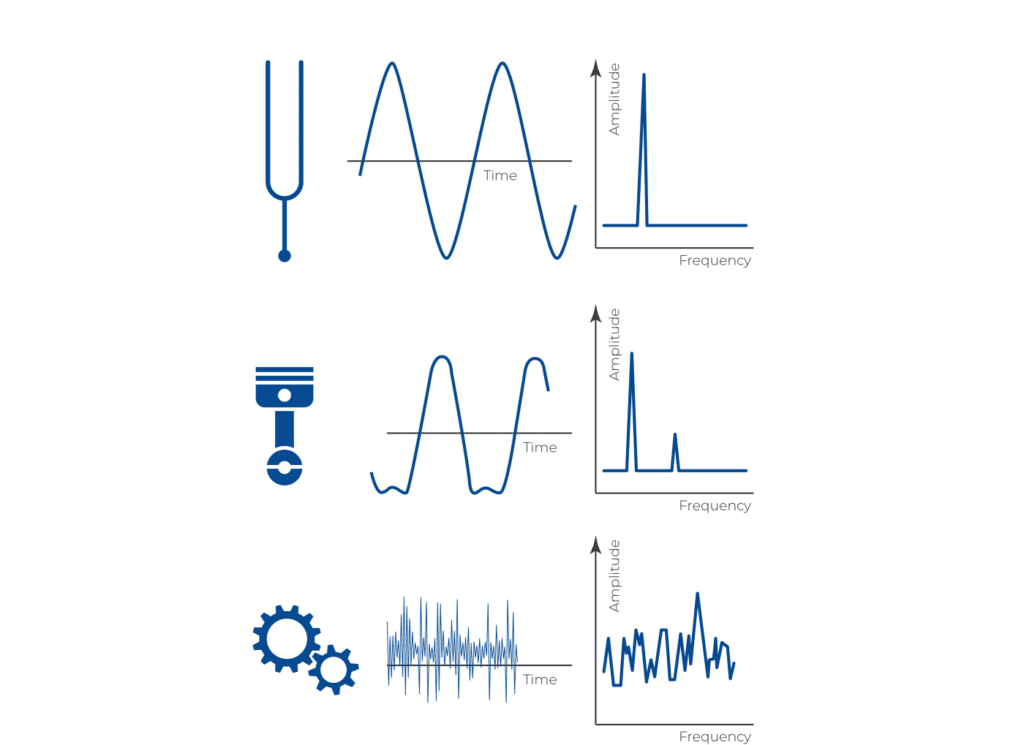

A spectrogram is a visual representation that maps the vibration amplitude against frequency over time, effectively uncovering the diverse components of a vibration signal. This graphical tool is pivotal for analyzing complex signals composed of multiple frequencies, as it breaks down these components to display how amplitude varies with frequency. This breakdown is crucial for identifying the existence of different vibratory elements within a signal, especially when these elements overlap or change over time.

By providing a detailed overview of how vibration characteristics evolve, a spectrogram serves as an essential tool for diagnostics, maintenance, and research. It allows analysts to discern patterns, transient events, and steady-state conditions within the signal, facilitating the identification of normal operational behaviours versus potential faults. The ability to visually distinguish these components helps in pinpointing specific issues, such as mechanical wear or operational inefficiencies, and supports the development of targeted interventions to mitigate or eliminate the source of undesirable vibrations.

Why is frequency analysis necessary for diagnostic purposes?

Frequency analysis is indispensable for diagnostic purposes because it dissects signals into their individual components, enabling the precise identification of the sources behind undesirable vibrations. This process is essential for isolating specific mechanical or operational issues, such as shaft rotation speeds or gear tooth meshing frequencies, which may not be apparent from a general observation of the vibration signal. By revealing these distinct signal components, the analysis provides a clear path to understanding the root causes of vibrations and formulating effective solutions.

The method’s value lies in its ability to detect and analyze periodic frequency components that correlate with the machines or structure’s operational characteristics. Identifying these components allows engineers and technicians to pinpoint the exact elements or conditions contributing to the vibration. This targeted approach not only facilitates more accurate maintenance and repair strategies but also enhances the overall reliability and efficiency of the equipment.

What type of sensors are used for vibration testing?

For vibration testing, several types of sensors are commonly used, each tailored to capture specific aspects with high precision and reliability. The primary sensors include:

Accelerometers: These are the most widely used sensors for vibration testing, capable of measuring acceleration forces that objects exhibit when they vibrate. Accelerometers are versatile and can provide data across a broad range of frequencies, making them suitable for a wide variety of applications, from industrial machinery maintenance to seismic monitoring.

Velocity Sensors: These sensors measure the speed of vibration, offering direct insight into the velocity component of oscillatory movements. Velocity sensors are particularly useful for low to medium frequency applications where they can accurately capture the rate of change in position over time.

Displacement Sensors: Focused on measuring the distance that an object moves from a reference point, displacement sensors are critical for assessing the amplitude of vibrations. They are especially valuable in applications where understanding the physical movement of a component is necessary, such as in monitoring the health of bridges or buildings.

Laser Vibrometers: These non-contact sensors use laser technology to measure vibration by detecting the Doppler shift of laser light reflected from a vibrating surface. Laser vibrometers are ideal for situations where physical contact with the vibrating object is impractical or could affect the measurement.

Strain Gauges: Although not used exclusively for vibration measurement, strain gauges can provide valuable data on the deformation of materials under vibrational stress. This information is crucial for assessing structural integrity and predicting fatigue life.

Micro-Electro-Mechanical Systems (MEMS): MEMS sensors are compact, integrated devices that can measure acceleration, and by extension, vibrations. They are increasingly used in portable and embedded applications due to their small size and low power consumption.

Each type of sensor has its own advantages and is chosen based on the specific requirements of the vibration testing task, including the frequency range of interest, the nature of the vibrations, and the environment in which the measurements are to be taken.