Hand-arm vibration measurement technique according to ISO 5349

The fundamental parameter used in the evaluation of hand-arm vibration is the vector sum of tri-axial vibration called ahv which is the basis for the calculation of daily exposure A(8). To identify the daily exposure, it is necessary to identify all the sources of vibration, which means identifying all working modes of tools (e.g. drilling with a hammer and without), and changes in the conditions of use of the device. This information is necessary for the proper organization of measurement and to include as many common tasks of the operator during which he is exposed to hand-arm vibration. Daily exposure should be calculated for each source of vibration.

After determining the sources of mechanical vibrations affecting the employee, the next step is to choose the most appropriate accelerometer mounting. According to ISO 5349, hand-arm vibration should be measured in place, or at the point of contact with the hand tool. The best location is the center of the handle, which is the most representative location. ISO 5349 suggests using lightweight sensors to reduce measurement errors. Measurements directly at the hand are performed using special adapters and measurement in all three axes is recommended.

Typical vibration exposure consists of short periods in which the operator is in contact with the tool. Measuring time should include a representative tool operation time and the measurement should start from the moment the vibrating device is touched and end when the contact is broken or the vibration stops (ISO 5349-2:2001).

ISO 5349-2 about improved methods for the assessment of vibration risk

The evaluation of vibration exposure as described in ISO 5349-1 is solely based on the measurement of vibration magnitude at the grip zones or handles and exposure times. Additional factors, such as gripping and feed forces applied by the operator, the posture of the hand and arm, the direction of the vibration, the environmental conditions, etc., are not taken into consideration. ISO 5349-2, being an application of ISO 5349-1, does not define guidance to evaluate these additional factors. However, it is recognized that reporting all relevant information is important for the development of improved methods for the assessment of vibration risk (ISO 5349-2:2001).

SV 103 Personal Hand-Arm Vibration Exposure Level Meter

The study has been performed with the SV 103, SVANTEK’s vibration exposure level meter that meets ISO 8041:2005 and is designed to perform measurements in accordance with ISO 5349-1 and ISO 5349-2 with special adapters mounted on the operator’s hand. Inside the hand adapter is the latest MEMS accelerometer and a contact force sensor.

Photo 3. SV 103 Hand-arm Vibration Exposure Meter

Contact forces act between the hand and the vibrating surface: the push/pull force and the gripping force. The need of simultaneous assessment of the contact forces and vibration magnitudes has been universally recognized and reflected in ISO 15230.

Figure 1. Examples of contact forces measurement given by ISO 15230

Both acceleration and contact force values are displayed clearly on the OLED screen, which has very good visibility and contrast. During the measurement, the instrument was powered by its rechargeable batteries. The SV 103 was attached to the arm of the operator, and the accelerometer was mounted on the hand. The cable was secured with a mounting band on the wrist not interfering with working activities.

The measurement task

The task was to drill four holes in a reinforced concrete block and this was performed by 3 operators. Each operator drilled the first two holes without gloves and then two holes with ISO 10819:1996 certified anti-vibration gloves on. The task was performed with the hammer function of the drill enabled (a model DeWALT D25103 with a manufacturer-stated vibration amplitude of 9.2 ms-2 in accordance with IEC 60745).

Photo 4. Typical mounting of SV 103 vibration exposure level meter on

an operator’s arm

Measurement results

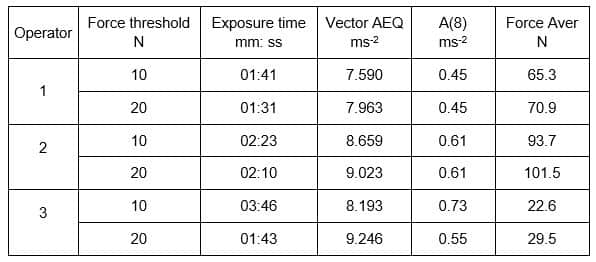

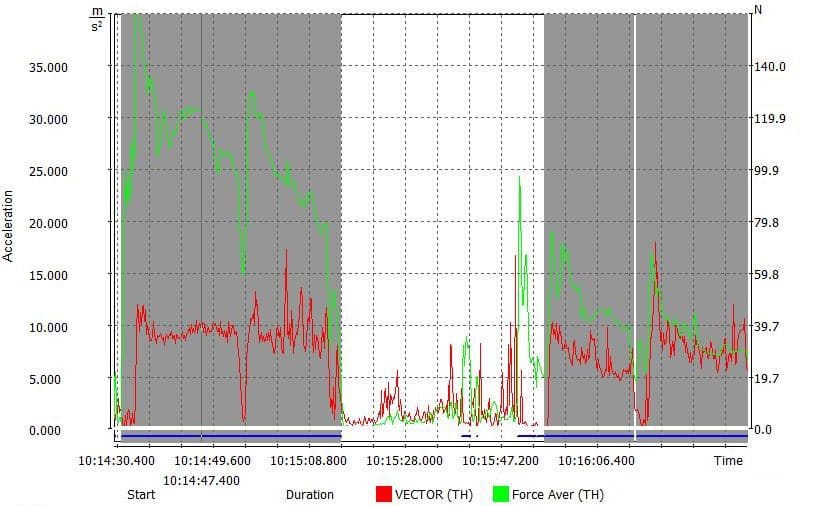

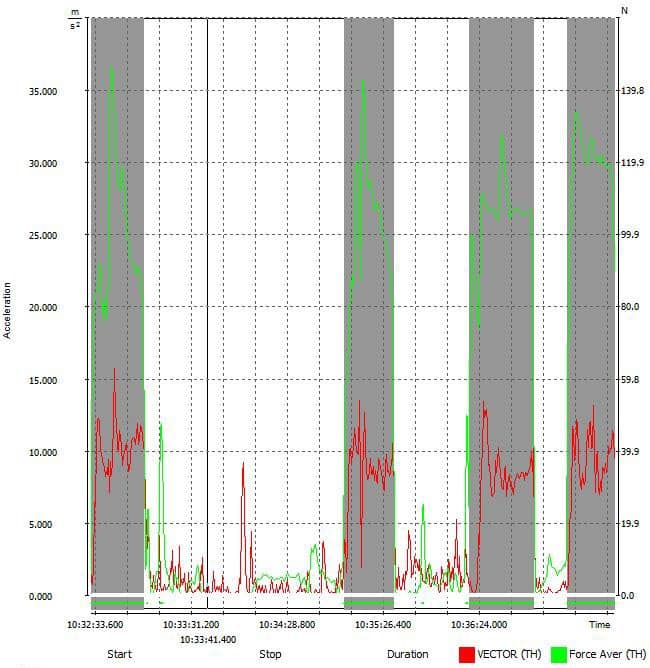

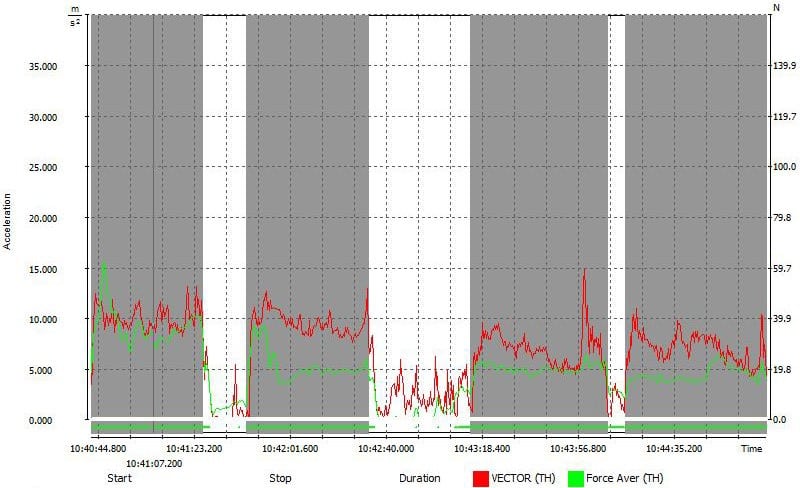

The SV 103 vibration exposure level meter recorded the time history of the ahv vector expressed in ms-2 and Contact Force expressed in Newtons (N) with a logging step of 200 ms for each of the 3 tasks (Figures 2, 3, 4). The data was further analyzed with SVANTEK’s Supervisor software (Svantek Sp Z o.o., 2014).

Using tools provided by the software, the time history of contact force values was used to determine the time of exposure of the operators to mechanical vibrations from the drill.

Depending on the contact force values, the following results have been obtained:

Table 1. Measurement results for 3 tasks

Figure 2. Time history of ahv vector and contact force (Operator 1)

Figure 3. Time history of ahv vector and Force (Operator 2)

Figure 4. Time history of AEQ vector and Force (Operator 3)

Verification of exposure time with 1/3 octave analysis

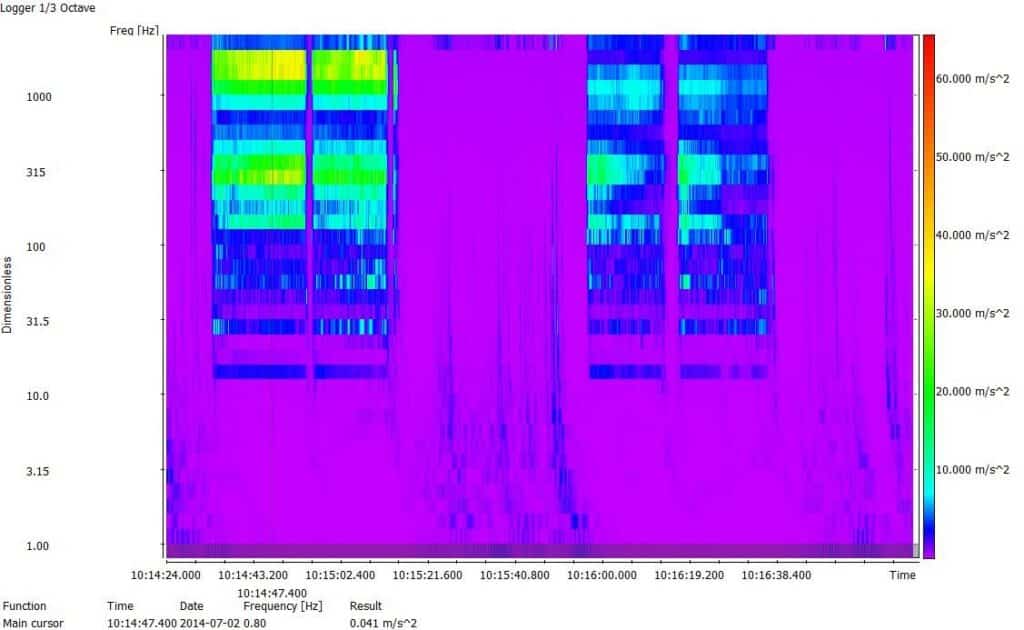

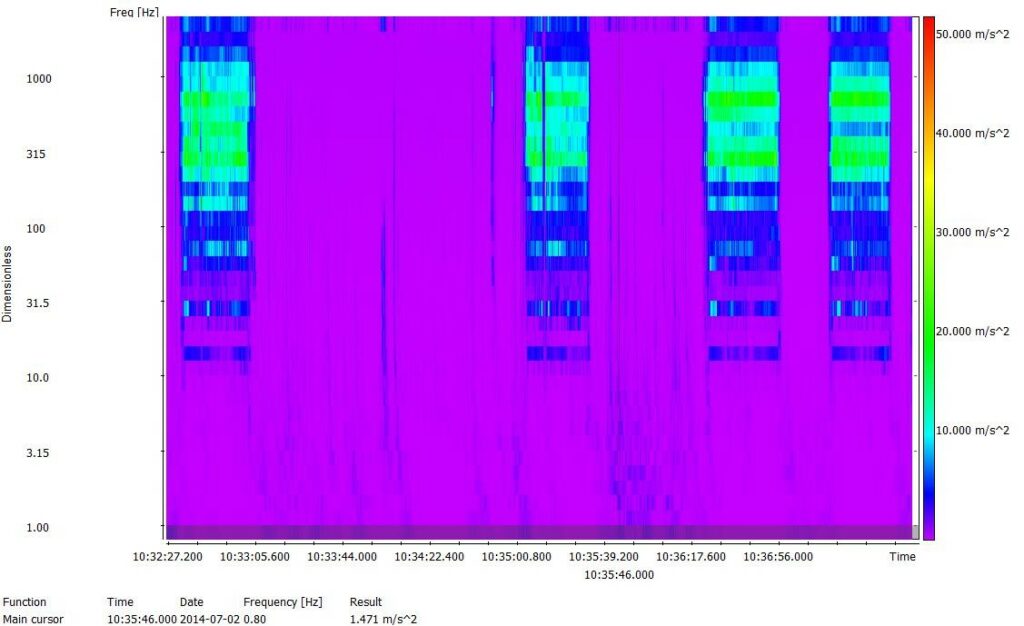

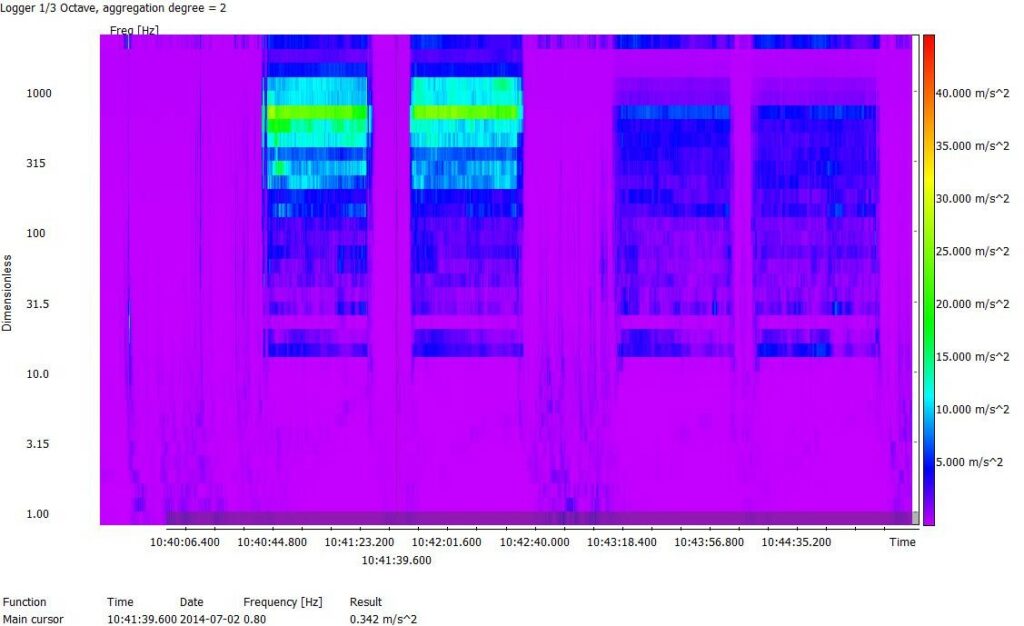

Additionally, the 1/3 octave spectrogram was analysed to determine the repeatability of the frequency contents for the selected exposure times for each operator (Figures 5, 6, 7).

Figure 5. Spectrogram of 1/3 octave (Operator 1)

Figure 6. Spectrogram of 1/3 octave (Operator 2)

Figure 7. Spectrogram of 1/3 octave (Operator 3)

Results and Conclusions

- The average contact force data analysis showed that Operator 2 used the biggest force whilst Operator 3 used the smallest amount of force when performing the task (Table 1). It is worth noting at this point that each operator’s posture was different – especially Operator 2, who leaned on the tool. This effect has been characterized in the Technical Report CEN/TR 16391:2012, which says: “Awkward and strained postures will tend to result in higher than necessary coupling forces between the hand and the handle of the machine“.

- For each operator, the daily exposure A(8) values were calculated based on exposure time indicated by the contact force thresholds. As per ISO 5349-2, short periods where the force values exceeded the threshold for less than 8 seconds were excluded from the calculation.

- For operators 1 and 2 the threshold of 20 N appeared sufficient to determine exposure times but in the case of Operator 3 the force threshold of 20 N appeared too high as the time period excluded large amounts of the sample. The selection of a 10 N threshold appeared to be correct in this case. Based on this phenomenon, the relationship between average contact force and the contact force threshold has been revealed. According to the study, the value of the contact force threshold should be set significantly lower than the average value for the considered time period.

- Results of A(8) for each operator show the relation between contact force values and vibration magnitudes and therefore contact force should be taken into consideration when evaluating the daily exposure.

- The analysis of the 1/3 octave spectrogram proved the selection of exposure times to be correct and additionally helped to evaluate the efficiency of anti-vibration gloves usage. The spectrogram clearly showed 4 activities for all operators, however, the spectrum for Operators 1 and 3 contained lesser values on higher frequencies for the last two drills resulting from the use of anti-vibration gloves. The spectrogram for Operator 2 (Figure 6) showed all holes drilled at a similar frequency content despite the use of anti-vibration gloves. These results show that an increase of contact force may reduce the efficiency of anti-vibration gloves significantly.