A sound level meter is a device that measures:

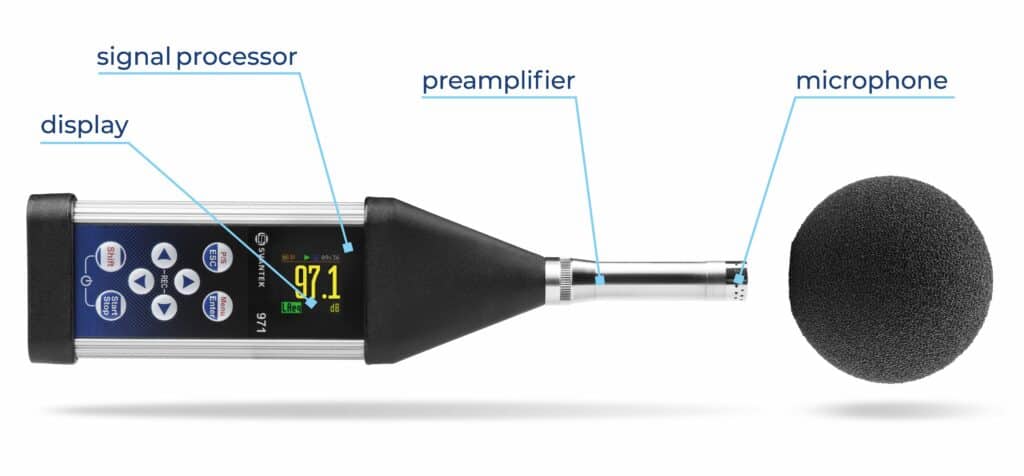

Sound level meters are also known as noise meters, decibel meters, or dB meters. Following BS EN 61672, noise level meters are composed of a microphone, a preamplifier, a signal processor, and a display that displays noise results. Hand-held noise level meters are usually battery-powered and feature a triangular tip and windscreen on top.

It can be a challenge to find the right sound meter for your specific needs. First, you must decide how the sound level meter will be used. Typically, professional sound pressure measurements follow standardized procedures that provide requirements for the type of sound meter. If you need to measure noise for your interests, a mobile application is just as good as purchasing a market sound level meter.

The following are the most common types of professional sound measuring applications:

There are two main types of pro sound meters:

These are the most accurate and expensive types of noise meters. They are typically used in professional measurements such as environmental noise (traffic noise, railway noise, aircraft noise), building acoustics, engineering measurements, or sound power.

These are less expensive and still provide accurate measurements. Class 2 sound level meters are typically used in environments such as offices, classrooms, or general industrial facilities.

Unless otherwise indicated in the measurement standard, class 2 sound level meters are generally accepted for workplace noise surveys.

There are a few factors to consider when choosing a noise level meter:

If you’re measuring environmental noise, you’ll need a Class 1 sound level meter. For industrial sound measurements, a Class 2 sound meter level meter will be good enough.

Most sound level meters have a noise levels range of 30-130 dB. The range that you need depends on the object you are measuring. For environmental noise measurements, you may need a lower range than 25 dB but not necessarily up to 140 dB. In the case of industrial noise, you will need the upper level to be at least 140 dB.

Class 1 meters are more expensive than Class 2, but both will give you accurate sound measurements as long as they meet the requirements of the BS EN 61672-1 standard.

The BS EN 61672-1 is an international standard that specifies the performance criteria for professional sound pressure level meters. There are two performance categories specified by this standard: class 1 and class 2.

The following are the most essential components for sound level meters that comply with this standard:

In general class 1 sound level meters are more accurate and more expensive than Class 2 sound meters.

Acceptance limits for variances in measured decibel levels at specific frequencies in the range of 10 Hz to 20 kHz are one of the most essential specifications of BS EN 61672-1:

In practice, this suggests that class 2 sound level meters are not a good option for measuring higher frequencies (for example, cleaning machine parts using compressed air).

The BS EN 61672-1 criterion for the linear operating range is not overly rigorous in terms of decibels, as they demand only 60 dB dynamics between the lowest measured dB and the highest. Professional noise level meters typically offer a much wider operating range, for example, the SV 971A offers 110 dB from 27 dB to 137 dB. The word “linear” is the most important phrase in this context since it indicates that the precise measurements in the dB operating range fulfill frequency response requirements.

The temperature operating range for a sound level meter that meets BS EN 61672-1 should be from -10°C to 50°C for class 1 and 0°C to 40 °C for class 2. In practice, this implies that class 2 sound level meters are not appropriate for accurate measurements in areas where the temperature drops below 0°C (for example, food processing plants).

For environmental noise measurements, you may need a lower range than 30 dB but not necessarily higher than 130 dB. In the case of industrial sound, you will need the upper level to be at least 140 dB Peak (the highest sound pressure level).

Depending on the measurement application, you will use class 1 or class 2. Class 1 is required for environmental noise and building and room acoustics. For occupational noise, class 2 is usually accepted unless the noise is dominated by high frequencies. If sound level measurements are taken in negative temperatures, class 1 is required.

We’ll go through the finest Svantek professional sound level meters for classes 1 and 2 below. They’re all digital noise level meters, which means they convert noise levels into decibel readings on a screen in decibel units.

The SVAN 979 is the top-of-the-range class 1 integrating sound level meter. It has been on the market for more than ten years, indicating that its software is well established and stable. The meter is packed with a diverse set of features, making it ideal for a wide range of tasks. If you’re looking for a sound level meter to measure noise in extremely quiet places, this is the one to use since it measures down to 12 dBA (even further with special microphones)! It also has an integrated program for conducting sound insulation measurements, including a signal generator that may generate pink noise and white noise. Furthermore, the meter can measure vibration by connecting the vibration sensor instead of the microphone.

If you’re on a budget, the SVAN 977 may be worth considering, which is a comparable model. Some of the features, such as the noise generator, are not included and others are optional, but they all impact on price.

The SV 971A is a third sound level meter in this comparison. This is a new generation sound level meter, which explains why it’s smaller than the 979 and 977. The SV 971A is the best choice for individuals who just want to measure noise without vibrations. Because of the small size, the display type is restricted, but all noise data may be viewed on your smartphone or tablet’s screen thanks to a sound level meter app. The SV 971A is also the most affordable professional noise level meter.

The SV 973 is a class 2 sound level meter, which means it’s an ideal tool for measuring noise levels in workplaces. It’s also an excellent meter for measuring sound levels in classrooms with options for the measurement of speech transmissibility and reverberation time. The class 2 designation indicates that the meter is intended to measure sound waves only in temperature conditions above 0° C and a limited frequency range to 10 kHz, although it is still a professional type of meter.

According to BS EN 61672, frequency weighting is a difference between the frequency weighted signal indicated on the meter display and the corresponding level of a constant-amplitude sinusoidal input signal.

Most sound level meters use A, C, and Z frequency weightings. The most commonly used is A-weighting, as it represents human hearing and is used for LAeq measurements. The C filter uses less attenuation on lower frequencies than A-weighting. For this reason, C-weighting is used to assess low frequencies in the signal by the difference between LCeq and LAeq levels. For the same reason, C-weighting is also used for peak sound level measurement. The Z-weighting has a flat frequency response from 10 Hz to 20 Hz and is often used for frequency spectrum measurement in octave bands.

A noise dosemeter is a small sound level meter that is attached to a person’s clothes and is worn during the workday to measure noise exposure and noise dose. Following IEC 61252 noise dosemeters meet specifications for class 2 sound level meters.

The noise exposure level LEX is calculated by noise dosemeters on a basis of LAEQ that is normalized to 8 hours. The sound exposure level LAE is a time-averaged LAEQ during the averaged time interval normalized to 1s.

Sound level meters are used to measure sound pressure levels. They are important tools for environmental noise control, product design, and many other applications. To ensure accurate measurements, it is important to calibrate your sound meter regularly. In this section, we will discuss the process of calibrating a sound level meter and provide some tips on how to do it correctly.

To verify the sound pressure level meter readings, a sinusoidal sound pressure level produced by a sound calibrator is used as a reference source in acoustical calibration. To calibrate the sound level meter, it must be adjusted to the level produced by the sound calibrator.

When the meter is adjusted to the calibrating signal, we’re talking about calibration. When no changes are required, the calibration check occurs.

The calibration should generally be completed before taking a series of measurements. The calibration should be verified (without adjustment) after measurements to compare the readings before and after.

For class 1 noise level meters the calibrator shall conform to the class 1 specifications of BS EN 60942. For class 2 noise level meters, the sound calibrator shall conform to either class 1 or class 2.

Unless it is regulated by local standards, the sound level meter shall be verified in UK traceable laboratory at intervals not exceeding 2 years.