Development Of Low-Cost Noise Monitoring Terminals (NMT) Based On MEMS Microphones

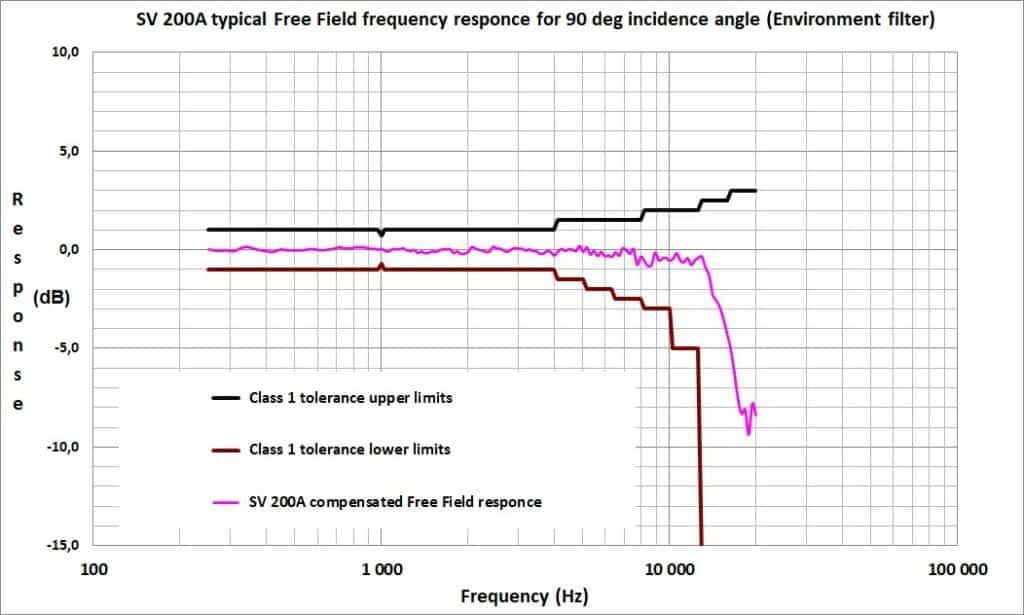

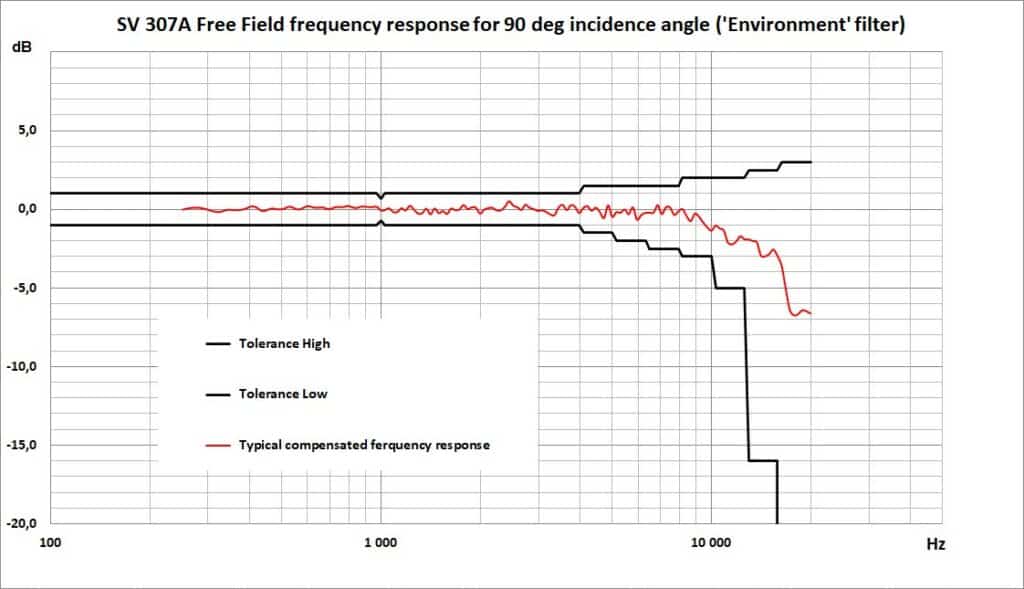

The article shows and discusses an example of NMTs with MEMS microphone meeting class 1 by IEC 61672-1.

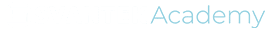

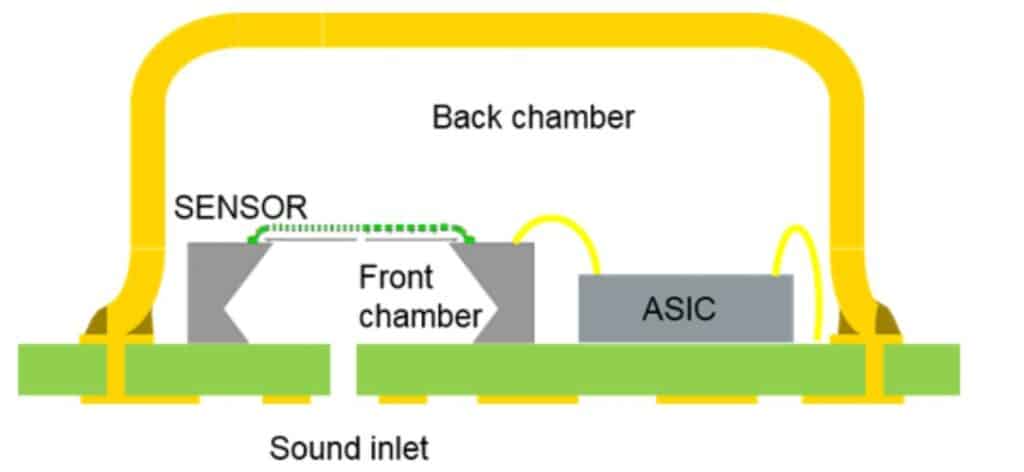

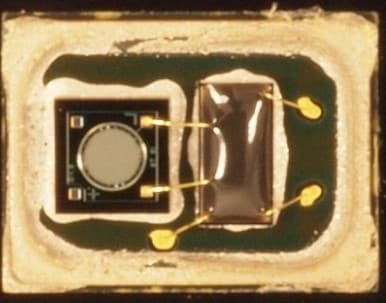

The rapid development of MEMS microphones (Micro-Electro-Mechanical Systems) in the last decade years made it possible to use them in noise measurement instrumentation meeting the IEC 61672-1 specification. Fifteen years ago, the available MEMS microphones offered only a 60 dB dynamic range, whereas modern MEMS microphones offer 100 dB dynamics. Such a wide dynamic range of MEMS microphones, along with their improved repeatability and long-term stability, enabled the development of low-cost noise monitoring terminals for noise monitoring. In particular one of such NMTs (Svantek SV 307A) offers the linear measurement range of 30 dBA Leq÷ 128 dBA Peak which proves to be optimal for urban noise monitoring applications.

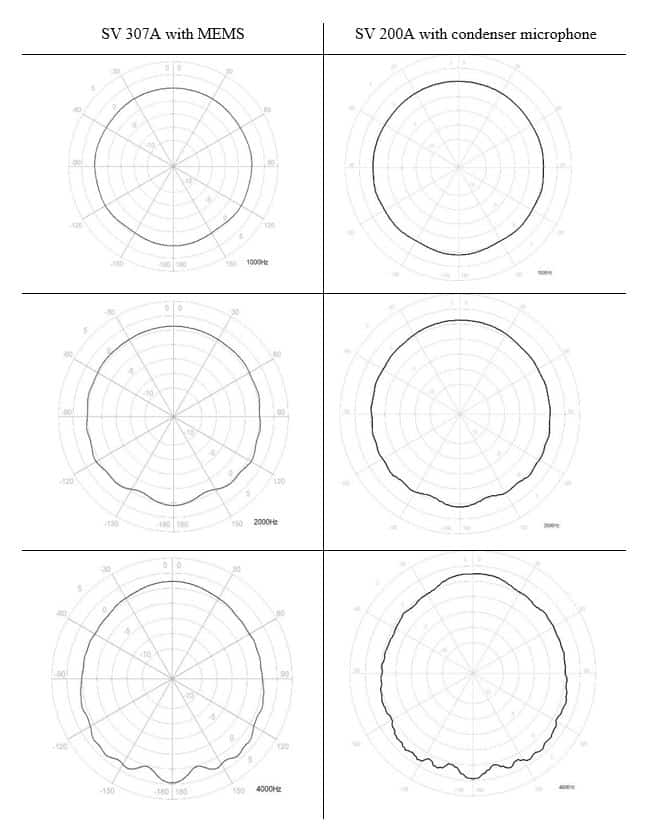

A low MEMS microphones cost enables the development of innovative designs for low-cost noise monitoring terminals with features such as a multi-microphones arrangement for a dynamic system check.