Comprehensive Overview, Techniques, Applications, and Instrumentation

In the UK’s industrial landscape, understanding and effectively managing machine vibration is paramount for ensuring the health and efficiency of industrial machinery. Machine vibration plays a crucial role in assessing dynamic conditions that affect machinery, such as balancing issues, bearing flaws, and component stress.

Machine vibration refers to the oscillations or movements generated by a machine or its components during operation. In the UK, where adherence to standards like BS ISO 20816-1 is critical, the measurement of machine vibrations typically involves the use of accelerometers and vibration meters to evaluate vibration amplitudes and frequencies.

The vibration amplitude, which indicates the extent of mechanical parts’ movement, is measured in micrometers, millimeters, or meters, quantifying vibration acceleration, displacement, or velocity.

Common causes of machine vibration in the UK include imbalanced loads, missing balance weights, and worn or damaged bearings. Early detection of these issues through vibration measurements is key to preventing potential machine failures and maintaining machine reliability.

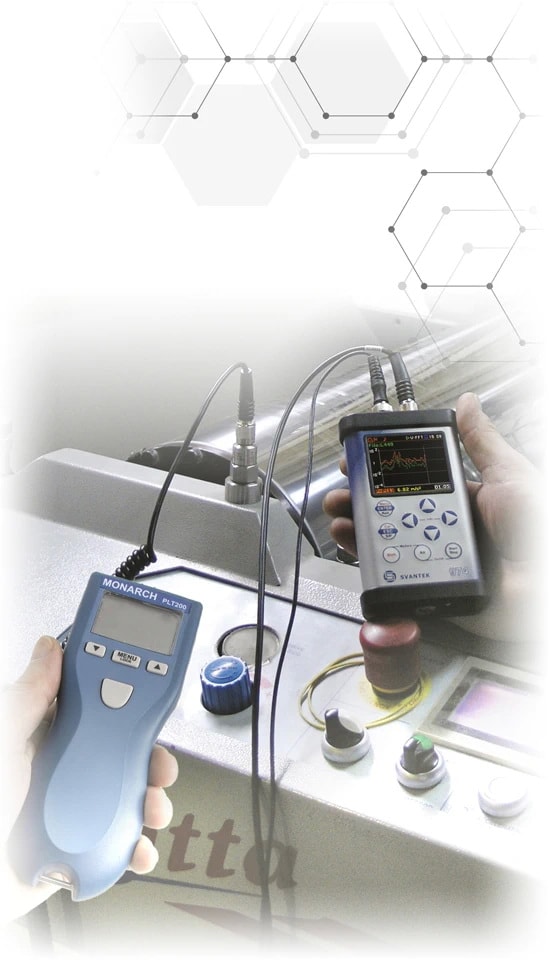

In the UK market, machine vibration measurements employ accelerometers and vibration meters to gauge the amplitudes and frequencies of vibrations. These instruments are integral to understanding and managing the oscillations produced by machines during operation, thereby playing a crucial role in preserving machine health and performance.

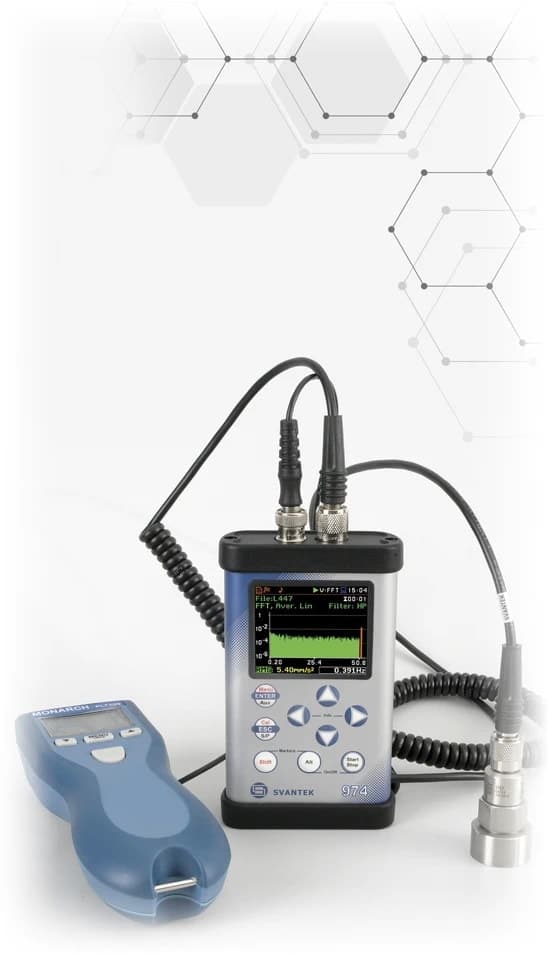

In compliance with BS ISO 2954, a Machine Vibration Meter in the UK comprises a vibration transducer, an indicating unit, and a power supply system. This device is essential in assessing machine vibrations, aiding in the early detection of faults, minimizing maintenance costs, and preventing unexpected machine failures.

The primary goal of machine vibration measurement is to identify its causes, thereby reducing the likelihood of machine breakdowns or assessing the machine’s condition. This process is vital for pinpointing mechanical issues, ensuring optimal machine performance, and averting unforeseen machine breakdowns.

Machine vibration reduction involves ensuring the correct placement of all balance weights and inspecting bearings for wear or damage. Vibration analysis is instrumental in identifying faulty components, contributing to smooth and efficient machine operation. By utilizing vibration measurement tools and techniques, UK professionals can effectively monitor machine conditions, optimizing performance while reducing downtime and repair costs.

Predictive maintenance, a strategy that utilises machine vibration data and other metrics, is increasingly being adopted in the UK. This approach facilitates early fault detection, reducing maintenance costs and preventing unexpected machine failures.

Machine vibration trend comparison involves analyzing the latest measurement results against historical data. This comparison enables early fault detection and assists in developing effective preventive strategies.

The ISO 20816-1 standard guides Machine Vibration Measurement Techniques in the UK. These techniques include the placement of accelerometers, setting appropriate measurement parameters, executing the measurement, and interpreting the results. The ISO standard aids in accurately collecting and analyzing vibration data, identifying potential faults like bearing defects, misalignment, and imbalance, and prompting timely corrective actions.

The vibration magnitude, denoting the maximum value of the broadband vibration energy in units of RMS velocity, is measured in micrometers for displacement, millimeters per second for velocity, and meters per square second for acceleration.

For accurate machine vibration analysis, the accelerometer should be mounted on the machine part under test, typically on a flat, clean surface, as per BS ISO 20816-1 guidelines. Measurements are recommended in three orthogonal directions: axial, radial horizontal, and radial vertical.

The ISO 20816-1 standard specifies machine vibration measurement settings for the UK market. These include parameters such as frequency range, transducer type, and units of measurement, along with ensuring minimal background noise and vibrations for accurate readings.

Machine vibration measurements are conducted once the accelerometer is properly attached and settings are configured. Measurements are taken for a specified duration, recording data on acceleration, velocity, or displacement.

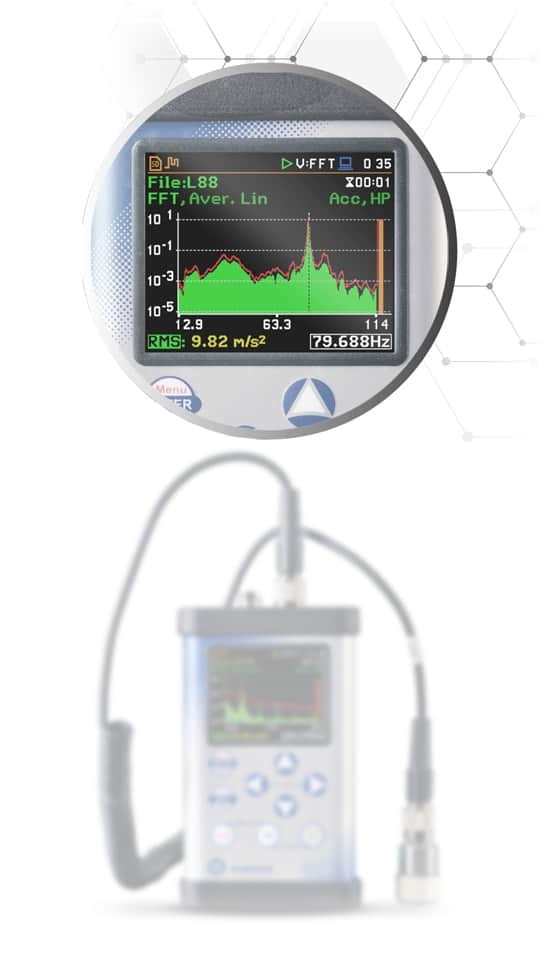

Interpretation of machine vibration results in the UK, as guided by BS ISO 20816-1, often involves using RMS velocity (vrms). Exceeding the ISO-specified limits indicates potential issues with machine health. Advanced frequency analysis like Fourier Transform (FFT) is employed to pinpoint specific fault conditions.

In the UK, BS ISO 20816-1 lists applications for machine vibration measurements, including non-rotating parts and rotating shafts. For non-rotating parts, a seismic transducer senses the absolute velocity or acceleration of components such as the bearing housing. For rotating parts, a non-contacting transducer measures the vibratory displacement between the shaft and a structural member.

Instrumentation in machine vibration measurement is crucial. This includes using specific vibration meters with appropriate specifications, considering their operating environment, and employing the correct transducers.

BS ISO 2954 provides specifications for vibration analysis instruments measuring vibration severity. BS ISO 10817-1 specifies instruments for shaft vibration, and BS ISO 5348 outlines specifications for mounting accelerometers, also applicable to velocity transducers.

As defined by BS ISO 2954, the Machine Vibration Meter is a combination of a vibration transducer, an indicating unit, and a power supply system, operating within a frequency range of 10 Hz to 1,000 Hz. The instrument may feature additional or modified filters to accommodate specific measurement needs.

Essential Nature of Machine Vibration Understanding: Recognizing and effectively managing machine vibration is crucial for the health and performance of industrial machinery in the UK.

Measurement and Analysis of Machine Vibration: The use of accelerometers and vibration meters to measure vibration amplitudes and frequencies is key for accurate assessment and management of machine vibrations.

Compliance with ISO 20816-1 Standard: Adherence to this standard is critical for proper vibration measurement techniques, which includes accelerometer placement, measurement execution, and interpretation of results.

Predictive Maintenance Using Vibration Data: Utilizing machine vibration data for early fault detection is vital in minimizing maintenance costs and preventing unexpected machine failures.

Instrumentation for Vibration Measurement: The use of specific instruments, as outlined in ISO standards, is essential for accurate vibration assessment and ensuring machine health and performance.